How Long Does It Take for Epoxy Resin to Dry: Drying Times

Understanding Epoxy Resin Drying

Epoxy Resin Curing Process

Epoxy resin curing is a chemical reaction between resin and hardener that results in a hard and durable finish. This process is influenced by a range of factors that affect how long it takes for epoxy resin to dry. Curing times can vary from a few hours to several days, depending on the type of epoxy and environmental conditions.

Different epoxies have different curing times. For instance, Upstart Epoxy Deep Pour has a dry time of 6 hours, whereas ArtResin offers a quick 30-minute working time, even though it takes about 72 hours to fully set (Upstart Epoxy).

Factors Influencing Drying Time

Several factors play a crucial role in determining how long it takes for epoxy resin to dry. Understanding these factors can help you achieve optimal results.

-

Environmental Conditions:

- Suggested humidity levels should be kept below 85%, ideally between 50-60%. Changes in humidity can lead to issues like blushing, cloudiness, loss of clarity, foaming, or premature curing of the epoxy (WiseBond).

- The ideal temperature for mixing ArtResin epoxy resin is between 75 and 85 degrees F. Warmer temperatures accelerate curing, while colder temperatures decelerate it.

-

Type of Epoxy Resin:

- Different types of epoxy resins have variable drying times due to their compositions and intended uses. Faster curing products contain more curing agents, which can cause the epoxy to harden within a few minutes (Upstart Epoxy).

-

Thickness of the Application:

- The thickness of the epoxy layer impacts the drying time. A deeper pour takes longer to cure compared to a standard, thin layer.

| Epoxy Type | Working Time | Full Cure Time |

|---|---|---|

| Upstart Epoxy Deep Pour | 6 hours | 72 hours |

| ArtResin Fast Cure | 30 minutes | 72 hours |

For more detailed information on epoxy and its applications, check our what is epoxy resin and how to cure epoxy resin articles. If you encounter sticky resin issues or improper curing, our section on Troubleshooting Drying Issues provides practical solutions.

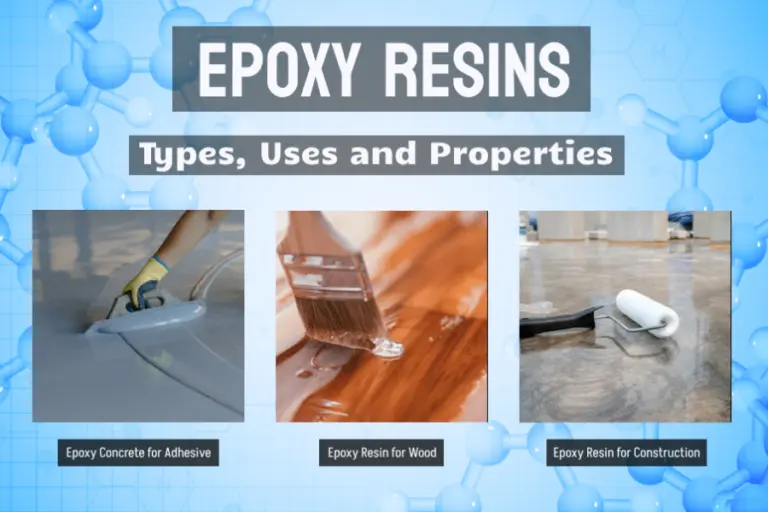

Types of Epoxy Resin

When working with epoxy resin, it’s important to choose the right type for your project. Different resins have various drying times and properties, making them suitable for specific applications. Here are three common types you might consider for your home renovation projects.

UV-Cured Epoxy

UV-cured epoxy resin is popular for projects that require a fast curing time. This type of epoxy hardens when exposed to ultraviolet light, making it ideal for applications where time is of the essence. UV-cured epoxy is often used in jewelry making, small repairs, and coating surfaces.

- Advantages: Quick drying, minimal mixing required, high clarity.

- Disadvantages: Requires UV light source, limited working time.

To learn more about how to use UV-cured epoxy, visit our guide on how to use epoxy resin.

Water-Dispersed Epoxy

Water-dispersed epoxy resins are designed to be diluted with water, making them a more environmentally friendly option. These resins are commonly used in coatings, adhesives, and paints. They offer good adhesion and durability, while also being easier to clean up.

- Advantages: Environmentally friendly, easy cleanup, good adhesion.

- Disadvantages: Longer drying time, may not be as strong as other types.

| Feature | Water-Dispersed Epoxy |

|---|---|

| Initial Setup Time | 1-2 hours |

| Full Cure Time | 24-48 hours |

For more details on choosing the right epoxy, check out what is epoxy resin.

High-Temperature Epoxy

High-temperature epoxy resins are formulated to withstand extreme heat. They are ideal for applications that will be exposed to high temperatures, such as automotive repairs, industrial uses, and certain types of crafting. These resins provide excellent strength and thermal stability.

- Advantages: High heat resistance, strong bond, durable.

- Disadvantages: Longer curing time, may be more difficult to work with.

| Feature | High-Temperature Epoxy |

|---|---|

| Initial Setup Time | 2-4 hours |

| Full Cure Time | 24-72 hours |

If you’re planning to use high-temperature epoxy, visit our page on is epoxy resin heat resistant for more information.

Understanding these types of epoxy resin can help you choose the best one for your needs. Whether you’re sealing wooden surfaces, making jewelry, or tackling an industrial project, there’s a suitable epoxy for you. For more tips on working with epoxy, see our articles on how to epoxy resin a table top and how to clean epoxy resin off tools.

Tips for Faster Drying

Drying epoxy resin can be tricky, especially if you’re working on a home renovation project. Knowing how to optimize drying times can make your task much more manageable. Here, we will discuss two effective strategies: maintaining optimal environmental conditions and applying heat to accelerate drying.

Optimal Environmental Conditions

Creating the ideal environment for your epoxy resin is critical to achieving a smooth and prompt drying process. Keeping the humidity levels low and the temperature consistent are your best allies.

Humidity plays a significant role. It is vital to keep it below 85%, with the optimal range being between 50-60% (WiseBond). Higher humidity can lead to issues such as cloudiness, foaming, or premature curing.

Temperature is another crucial factor. Resin likes to work in the low 70s °F. Maintaining this range ensures that the resin cures appropriately without complications. If you’re working in colder weather, you might want to consider creating a controlled environment to keep the temperature stable.

| Environmental Factor | Optimal Range |

|---|---|

| Humidity | 50-60% |

| Temperature | Low 70s °F |

Applying Heat for Acceleration

Applying heat to your resin project can significantly decrease drying times. Heat accelerates the curing process, allowing you to achieve your results faster.

You can raise the temperature in your working area. Techniques such as using a resin ‘hot box’ or casting resin outside on warm days can be effective. Ensure the temperature is consistently above 70 to 75 °F throughout the curing period (Resin Obsession).

Another method involves using an oven. A warm oven, such as a 150°F toaster oven, can help speed up the curing process. However, it’s imperative to note that the oven used for curing resin should not be reused for food purposes afterward due to potential contamination (Resin Obsession).

Remember, when speeding up the drying process, always prioritize safety. Sudden temperature changes can cause stress in the material, leading to cracks or other issues. Therefore, gradually increase heat and closely monitor the curing process.

For a more comprehensive guide on how to cure epoxy resin, check out our detailed article.

By understanding and applying these tips, you can make your epoxy projects more efficient and achieve the best possible results. For additional methods and practical advice, visit our resources on how to add color pigment to epoxy resin, what are some good polishers for epoxy resin, and how to use epoxy resin on wood.

Troubleshooting Drying Issues

Encountering drying issues with epoxy resin can be frustrating, especially when you’re unsure how to address them. Understanding and troubleshooting these issues can save time and effort. This section will help you solve problems related to sticky resin and handling improper curing.

Sticky Resin Solutions

Sticky or tacky resin is a common problem in epoxy projects. Resin that remains sticky days after being poured will stay sticky indefinitely unless properly treated. To resolve this issue, follow these steps:

- Scrape Off Sticky Areas: Use a plastic scraper to remove any sticky or tacky resin.

- Fill with New Resin: Apply a fresh layer of epoxy resin on the affected area.

- Sand and Recoat: Once the new resin layer cures, sand the surface lightly and apply a second coat.

It’s crucial to mix the resin and hardener in the correct 1:1 ratio. Ensuring accurate measurement and thorough mixing helps avoid sticky resin.

Handling Improper Curing

Improper curing can occur due to several factors, including incorrect mixing ratios, overmixing, and using incompatible hardeners. Here are some tips for handling improper curing:

- Correct Mixing Ratio: Always stick to the 1:1 ratio of resin to hardener. Deviating from this ratio will prevent proper catalyzation.

- Avoid Overmixing: Mixing the resin and hardener for too long can introduce air bubbles and impede curing. Stir the mixture gently and steadily.

- Use Provided Hardener: Always use the hardener that comes with your resin kit. Mixing different brands or types can lead to curing problems (Resin Obsession).

- Follow Kit Directions: Adding excessive amounts of hardener or using a different hardener than indicated can reduce the pot time and cause premature curing.

To ensure proper selection and use, see our article on how to use epoxy resin.

By following these guidelines, you can troubleshoot and resolve common epoxy resin drying issues. For more information on epoxy resin handling, check out our articles on how to remove epoxy resin, how to cure epoxy resin, and how to clean epoxy resin.

Choosing the Right Epoxy

Selecting the right epoxy resin is essential for achieving the best results in your DIY projects. There are various types of epoxy resins available, each suited for different applications based on their unique properties. This section will help you understand how to match the epoxy to your application and ensure compatibility with surfaces.

Matching Epoxy to Application

When working with epoxy resin, it’s crucial to choose the one that best fits your specific project needs. Here are some common types of epoxy resin and their suitable applications:

- UV-Cured Epoxy: Ideal for applications requiring a quick cure under UV light. Commonly used in dental and jewelry making (Xometry).

- Water-Dispersed Epoxy: Suitable for coatings and adhesives that require water resistance. Perfect for marine applications.

- High-Temperature Epoxy: Used in high-stress environments like automotive and aerospace industries. It withstands high temperatures without degrading.

| Epoxy Type | Typical Applications | Cure Time |

|---|---|---|

| UV-Cured Epoxy | Dental, Jewelry Making | Minutes |

| Water-Dispersed | Marine, Coating, Adhesive | Hours |

| High-Temperature | Automotive, Aerospace | Hours to Days |

Make sure to refer to our guide on how long does it take for epoxy resin to dry to understand more about curing times for different epoxy resins.

Ensuring Compatibility with Surfaces

Ensuring that the epoxy resin is compatible with the surface you’re working on is key to a successful project. Each epoxy resin is formulated to adhere to specific materials and environmental conditions. Here are some tips:

- Adhesion: Ensure the epoxy is designed to bond well with your surface, whether it’s wood, metal, glass, or plastic. For instance, water-dispersed epoxies work well on wood, while high-temperature epoxies are better suited for metals.

- Surface Preparation: Properly preparing the surface by cleaning and sanding can improve adhesion. Check our guide on how to use epoxy resin on wood for detailed steps.

- Environmental Conditions: Some epoxies are more sensitive to humidity and temperature. High-temperature epoxies, for example, are formulated to perform well in extreme conditions.

For additional insights on dealing with different surfaces and epoxy types, visit our articles on how to epoxy resin a table top and does epoxy resin stick to plastic.

Remember, mixing resins and hardeners from different brands can cause issues. Always use the matched resin and hardener from the same brand to ensure proper curing (ArtResin).

Selecting the right epoxy and ensuring compatibility with different surfaces are critical steps in your renovation projects. For more information on epoxy resins, check our articles on what is epoxy resin and how to clean epoxy resin off tools.

Comparing Drying Times

Deep Pour vs. Standard Cure

When it comes to how long does it take for epoxy resin to dry, understanding the differences between deep pour and standard cure epoxy is vital. Deep pour epoxy, like Upstart Epoxy Deep Pour, has a flexible dry time of approximately 6 hours, while Art Resin takes around 30 minutes to become workable. However, both types generally require about 72 hours to be fully set and cured (Upstart Epoxy). Visit how to cure epoxy resin for more details on the curing process.

| Epoxy Type | Initial Dry Time | Fully Set |

|---|---|---|

| Deep Pour Epoxy | 6 Hours | 72 Hours |

| Standard Cure Epoxy | 30 Minutes | 72 Hours |

Fast Curing Epoxy Considerations

Fast curing epoxy resins are designed with a higher concentration of curing agents, enabling them to harden within a few minutes. While this can expedite your project, it also leaves little margin for error during application. Make sure you are well-prepared to apply fast curing epoxy to avoid mishaps.

| Fast Curing Epoxy Type | Working Time | Cure Time |

|---|---|---|

| General Fast Curing | Few Minutes | 24-48 Hours |

For a smooth and successful application, always have a solid plan and the right tools at the ready. Check out how to mix epoxy resin and how to pour epoxy resin for useful guidance.

To explore more about different types of epoxy and their applications, read our sections on what is epoxy resin and how to use epoxy resin.