Is Epoxy Resin Heat Resistant: Durability Guide

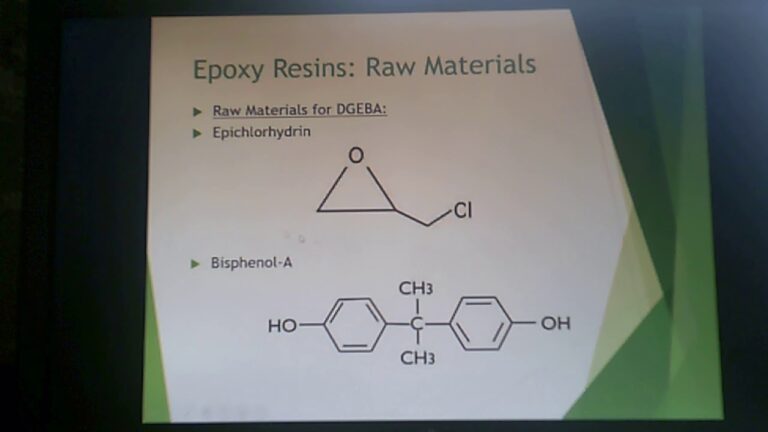

Understanding Epoxy Resins

Properties of Epoxy Resins

Epoxy resins are known for their versatile properties that make them ideal for various applications, especially within industrial and DIY contexts. One of the standout features of epoxy resins is their distinct aliphatic structure, which provides strong weather resistance and a high glass transition temperature (Tg) (Copps Industries). This structure enhances their capability to resist heat, making them a reliable choice for projects that require thermal durability.

In addition to heat resistance, epoxy resin boasts impressive high strength and chemical resistance. This makes it perfect for settings where exposure to corrosive substances is common. Epoxy resins also offer excellent electrical insulation properties, making them suitable for electronic applications. The combination of these properties ensures that epoxy resin can withstand demanding environments while providing a durable finish.

Applications of Epoxy Resins

Given its robust properties, epoxy resin finds applications in numerous industries. It’s widely used in the electrical industry due to its heat resistance and chemical resistance. Key applications include the construction of motors, generators, transformers, insulators, and printed wiring boards. The heat-resistant quality of epoxy resin ensures that these components can operate reliably under varying temperatures.

Epoxy resin is not limited to the electrical industry; it is also popular in home renovation projects, such as coating countertops and floors. Its durability and ability to create a glossy, hard surface make it a favorite among home renovators. Additionally, epoxy resin is used in the marine industry for building and repairing boats, thanks to its water-resistant properties.

For artists and craftsmen, epoxy resin is a go-to material for creating jewelry, art pieces, and other decorative items. Its ability to be mixed with pigments allows for creative and colorful projects.

Below is a table summarizing the key applications of epoxy resins:

| Industry | Applications |

|---|---|

| Electrical | Motors, Generators, Transformers, Insulators, Wiring Boards |

| Home Renovation | Countertops, Floors |

| Marine | Boat Building & Repair |

| Art & Craft | Jewelry, Art Pieces, Decorative Items |

For more details on working with epoxy resin, such as how to clean or polish it, visit our guides on how to clean epoxy resin and how to polish epoxy resin.

Epoxy resin is essential in various fields due to its heat resistance, chemical durability, and versatility. Whether you are a professional or a DIY enthusiast, understanding the properties and applications of epoxy resin can help you choose the right type for your project.

Heat Resistance of Epoxy Resins

When wondering “is epoxy resin heat resistant?”, it’s essential to understand the various factors that influence its thermal stability and performance. Epoxy resins are known for their remarkable heat resistance, which makes them suitable for a wide range of applications.

Thermal Stability Comparison

Epoxy resins are famed for their superior mechanical properties, which includes their ability to withstand high temperatures better compared to other types of resins. This is primarily due to their aliphatic structure, strong weather resistance, and high glass transition temperature (Tg) (Copps Industries).

To provide a clear comparison, here’s a table showcasing the thermal stability of epoxy resins against other common resin types:

| Resin Type | Thermal Stability (°C) |

|---|---|

| Epoxy Resin | 120 – 200 |

| Polyester Resin | 60 – 80 |

| Polyurethane Resin | 60 – 90 |

| Vinyl Ester Resin | 90 – 120 |

Factors Influencing Heat Resistance

Several factors come into play to determine the heat resistance of epoxy resins:

-

Curing Process: The curing process significantly impacts the thermal stability of epoxy resins. Proper curing ensures that the epoxy reaches its full potential in terms of strength and heat resistance. For more insights on how curing affects heat resistance, visit our how to cure epoxy resin guide.

-

Chemical Composition: The specific formulation of the epoxy resin plays a crucial role. The addition of certain hardeners and the inherent chemical structure of the resin contribute to its ability to withstand high temperatures.

-

Age and Exposure: Over time, and with exposure to varying environmental conditions, the heat resistance of epoxy resins may degrade. Regular maintenance is key to ensuring longevity. Learn how to maintain your epoxy surfaces by reading how to clean epoxy resin.

-

Temperature Control: During the curing process, the ambient temperature can affect the final heat resistance of the cured epoxy resin. Warmer temperatures facilitate faster curing, which can influence the thermal properties of the resin (Copps Industries).

Evaluating the thermal stability of epoxy resins can be done through processes like thermogravimetric analysis and testing adhesive strength measurements under varying temperatures.

By understanding the factors that influence heat resistance and comparing the thermal stability of different resin types, you can make an informed decision when selecting the best epoxy resin for your needs. Interested in learning more about epoxy resin uses? Check out what is epoxy resin for a comprehensive guide.

Epoxy Resin Curing

Understanding the curing process of epoxy resin is essential if you’re looking to utilize its full potential, especially for heat resistance and durability. Let’s dive into the curing process and its impact on heat resistance.

Curing Process

The curing process for epoxy resin involves mixing the resin with an appropriate curative, usually a hardener. This chemical reaction results in cross-linked thermoset structures, which dramatically impact the mechanical and chemical properties of the resin. The curing time can vary based on multiple factors, most notably temperature. Warmer temperatures facilitate faster curing, while colder temperatures can slow down the process. You can use a faster hardener or additional heat to speed up curing in colder environments.

Here’s a quick look at curing times under different temperatures:

| Temperature (°F) | Curing Time |

|---|---|

| 60 | 72 hours |

| 70 | 48 hours |

| 80 | 24 hours |

This data underscores the importance of temperature control during the curing process (Hairy Goddess).

To ensure a strong adhesive bond and achieve the desired properties, it is recommended to cure epoxy resin slowly and for extended periods. This approach solidifies the resin into a robust, high-strength material suitable for various applications, including flooring systems in commercial and industrial buildings, where heat resistance is crucial.

For detailed steps on curing epoxy resin effectively, check out our guide on how to cure epoxy resin.

Impact on Heat Resistance

The curing process directly affects the heat resistance of epoxy resin. Properly cured epoxy resins exhibit enhanced heat resistance, making them ideal for high-temperature applications. When the resin and hardener mix, they form a cross-linked structure, improving the thermal stability of the epoxy.

Proper curing transforms the resin into a substance that can withstand higher temperatures without losing structural integrity. The specific heat resistance can vary depending on the type of epoxy resin and the curing conditions, but it generally ranges between 150-300°F.

| Heat Resistance (°F) | 150-300 |

|---|

Factors such as extreme temperature fluctuations and UV exposure can weaken the resin over time, leading to yellowing and brittleness. To prolong the life and enhance the durability of epoxy resin, consider applying UV-resistant coatings.

For those interested in the nuances of heat resistance in cured epoxy resins, explore our article on is epoxy resin heat resistant.

Understanding these aspects will help you make informed decisions about using epoxy resin in your next home renovation project. Whether you’re considering floor applications or another project, knowing how to manage the curing process will prove invaluable. For tips on maintaining and polishing your epoxy resin projects, visit how to polish epoxy resin.

Epoxy Resin in Different Industries

Epoxy resin is a versatile material used across various industries due to its durability and heat resistance. Let’s explore how epoxy resin is applied in the electronics, transportation, and aerospace sectors.

Electronics Industry

Epoxy resins are invaluable in the electronics industry. They are employed to manufacture printed wiring boards, insulators, transformers, generators, and motors. Their excellent electrical insulation properties and ability to protect components in harsh environments make them ideal for these applications (Copps Industries). This ensures the longevity and reliability of electronic devices.

| Application | Benefit |

|---|---|

| Printed Wiring Boards | Electrical insulation, structural integrity |

| Insulators | Maintain dielectric strength |

| Transformers | Protection in extreme environments |

| Generators | Prolonged component lifespan |

| Motors | Enhanced heat resistance |

To learn more about the benefits and applications of epoxy resin in electronics, visit our article on what is epoxy resin.

Transportation Industry

In transportation, high-temperature epoxy resins are utilized to bond parts and provide protection from heat or environmental damage in vehicles like cars, trucks, motorcycles, electric vehicles (EVs), and boats. This application ensures components remain secure and durable under varying conditions, enhancing vehicle safety and performance.

| Vehicle Type | Application | Benefit |

|---|---|---|

| Cars | Bonding parts | Structural integrity |

| Trucks | Protect sensitive areas | Heat and environmental protection |

| Motorcycles | Enhance performance | Durability |

| Electric Vehicles (EVs) | Secure components | Efficiency |

| Boats | Maintain integrity | Resistance to water and heat |

For additional details on how to use epoxy resin in home projects, explore our related articles.

Aerospace Industry

In the aerospace sector, high-temperature epoxy resins play a critical role. They protect seals in engines and hold vital pieces of rockets, airplanes, satellites, drones, and missiles together. These resins are chosen for their ability to withstand extreme temperatures and mechanical stress.

| Aerospace Application | Benefit |

|---|---|

| Engine Seals | Temperature resistance |

| Rocket Construction | Structural integrity |

| Airplanes | Durability |

| Satellites | Protection against extreme conditions |

| Drones | Lightweight strength |

| Missiles | High-temperature performance |

Epoxy resin’s application in aerospace demonstrates its capacity for high-stress and demanding environments. For more insights on epoxy resin’s properties and uses, check out what is epoxy resin.

With its diverse applications, epoxy resin is a valuable material in multiple industries. By understanding its uses, you can better appreciate its role in improving the durability and functionality of various products. For more information on how to maintain and repair epoxy resin, visit our guide on how to clean epoxy resin.

Benefits and Drawbacks of Epoxy Resins

Advantages of Epoxy Resins

Epoxy resins are a powerhouse choice for home renovation projects due to their numerous benefits:

- Durability: Epoxy resin is known for its strength and resistance to environmental degradation, making it an ideal choice for applications demanding long-term durability (Carved).

- Adhesion: This versatile adhesive offers excellent adhesion and can bond well with various materials, including wood, metal, and fiberglass. This makes it suitable for coating surfaces, creating strong bonds, and laminating high-tech cloths like Kevlar and graphite (Artmolds).

- Chemical Resistance: Epoxy resin is highly resistant to corrosive substances, making it a perfect choice for industrial settings.

- Electrical Insulation: It provides excellent electrical insulation properties, making it suitable for electronics applications.

- Thermal Stability: Epoxy resin can withstand moderate temperatures, adding to its versatility in different environments. For more insights, see our guide on is epoxy resin heat resistant.

Here’s a quick comparison of features:

| Feature | Epoxy Resin | Polyester Resin |

|---|---|---|

| Strength | Excellent | Moderate |

| Adhesion | Excellent | Poor |

| Chemical Resistance | Excellent | Moderate |

| Electrical Insulation | Excellent | Poor |

| Durability | Excellent | Poor |

Limitations of Epoxy Resins

Despite their many advantages, epoxy resins come with their own set of limitations:

- Brittleness: While epoxy resin is strong, it can be brittle and prone to cracking under stress, especially compared to more flexible resins like polyester (Carved).

- Sensitivity to Temperature and UV Exposure: Exposure to extreme heat, direct sunlight, or UV rays can cause warping or melting of the resin. Proper handling and avoiding prolonged exposure to such conditions are crucial.

- Maintenance: Regular maintenance is essential for the long-term resilience of epoxy resin. This includes routine inspection and repair of any damage. For guidance on maintenance, explore our article on how to polish epoxy resin.

- Repair Challenges: Repairing broken or damaged epoxy resin can be challenging and might require specific techniques and materials, such as using the resin itself as a filler for severe damage. More details can be found in our article on how to remove epoxy resin.

For a deeper understanding of epoxy resin applications and handling, check out related resources like what is epoxy resin and how to use epoxy resin.

By understanding both the advantages and limitations, you can make informed decisions about using epoxy resin in your home renovation projects, ensuring that you get the most out of this versatile material.

Maintenance and Repair of Epoxy Resin

Proper maintenance and repair of epoxy resin can extend its longevity and enhance its performance. Understanding the durability and techniques for repair helps you ensure your epoxy resin projects remain in top shape.

Longevity and Durability

Epoxy resin is known for its impressive durability and strong adhesive properties. It’s resistant to a variety of factors, making it a reliable choice for numerous applications. Here are some key aspects of its longevity and durability:

- High Strength: Epoxy resin offers excellent adhesion, creating strong bonds with materials like wood, metal, and fiberglass (Artmolds).

- Chemical Resistance: Its high resistance to chemicals makes it well-suited for industrial settings (Artmolds).

- Temperature Stability: Epoxy resin can withstand moderate to high temperatures, providing thermal stability needed for construction and electronic applications (Sakshi Chem Sciences).

- Moisture Resistance: It is resistant to moisture, preventing damage in humid conditions.

| Property | Description |

|---|---|

| High Strength | Strong adhesion with various materials |

| Chemical Resistance | Withstands corrosive substances |

| Temperature Stability | Moderate to high heat resistance |

| Moisture Resistance | Resistant to moisture |

Repair Techniques

If your epoxy resin project gets damaged, there are various repair techniques you can use to restore its integrity:

- Cleaning the Damaged Area: Begin by cleaning the damaged area thoroughly. Removing dirt, grease, and any loose particles ensures a better bond for the repair.

- Internal Links:

- Sanding: Lightly sand the area around the damage to create a rough surface. This helps the new layer of epoxy resin adhere better.

- Internal Links:

- Applying New Epoxy: Mix a small batch of epoxy resin and apply it to the damaged area. Use a brush or spreader to ensure it fills all the gaps and covers the entire surface evenly.

- Internal Links:

- Curing: Allow the epoxy resin to cure as directed by the product instructions. Proper curing is critical for achieving maximum strength.

- Internal Links:

- Polishing: After the epoxy has fully cured, you may need to polish the area to match the surrounding finish.

For more detailed instructions, including safety tips and product recommendations, explore our other articles on epoxy resin, such as is epoxy resin out of style and how to use epoxy resin on wood. Proper maintenance and timely repairs can significantly extend the life of your epoxy resin projects, ensuring they stay durable and functional for years to come.