Is Epoxy Resin Toxic: Safety Considerations

Understanding Epoxy Resins

When working with adhesives, it’s crucial to understand the safety considerations, especially for something like epoxy resin. Epoxy resins are popular for their strong adhesive qualities and versatility in various projects, including home renovations, but it’s important to know if epoxy resin is toxic and the precautions you should take.

Epoxy Resin Toxicity Overview

Epoxy resin in its pure form is generally considered non-toxic, with a very small risk of damage from ingestion. However, the curing agents used in epoxy resins can present certain levels of toxicity (source). These agents typically include compounds like aliphatic polyamines, which are known to cause skin irritations such as toxic eczema or allergic contact dermatitis.

During the curing process, the resin and hardener chemically react to form a solid material, generating heat and releasing fumes. These fumes can be irritating to the skin, eyes, and respiratory system. Therefore, it’s essential to handle the material with care and use appropriate safety precautions.

Common Health Risks:

- Skin Irritation: Contact with uncured resin can cause dermatitis.

- Respiratory Issues: Inhaling fumes can irritate the respiratory tract.

- Eye Irritation: Fumes or splashes can cause eye discomfort.

| Health Risk | Symptoms |

|---|---|

| Skin Irritation | Redness, itching, rash |

| Respiratory Issues | Coughing, shortness of breath |

| Eye Irritation | Redness, watering, discomfort |

Common Risks of Epoxy Resins

While epoxy resins are generally safe when used correctly, there are some risks to be aware of. The most common risks stem from skin contact and inhalation during the handling and curing process.

Skin Contact:

The primary risk associated with epoxy resin is skin contact. Direct contact with uncured resin can lead to skin irritations like toxic eczema or allergic contact dermatitis. Washing the affected area thoroughly with soap and water can help minimize potential irritation.

Inhalation:

The fumes released during the curing process can cause respiratory irritation. It’s important to work in well-ventilated areas and consider wearing respiratory protection if ventilation is inadequate. Make sure to check out our guide on protective measures for respiratory safety while working with epoxy resins.

For more specifics on the risks of handling epoxy resin, read about how to handle and store epoxy safely.

By understanding the toxicity and associated risks of epoxy resins, you’re better equipped to take the necessary precautions in your home renovation projects. Always prioritize safety by using personal protective equipment like gloves and masks, and ensure proper ventilation when working with these materials. For more safety tips and guides on epoxy resin, you can explore topics like how to use epoxy resin and how to clean epoxy resin.

Safety Measures for Epoxy Resins

When working with epoxy resin, safety should be your top priority. Here are key safety practices, focusing on proper handling, ventilation, and personal protective equipment.

Proper Handling and Storage

To minimize the risks associated with epoxy resin, you need to handle and store it properly. Always read the manufacturer’s guidelines before you start. Keep the containers tightly sealed when not in use and store them in a cool, dry place away from direct sunlight. This prevents the resin components from degrading, which could lead to fumes or spillages.

| Safety Measure | Description |

|---|---|

| Proper Sealing | Always keep containers tightly closed |

| Cool Storage | Store in a cool, dry place away from sunlight |

For detailed steps, visit how to use epoxy resin and how to clean epoxy resin off tools.

Ventilation and Respiratory Protection

Proper ventilation is crucial when working with epoxy resin to dissipate fumes and prevent respiratory irritation (Missouri Poison Center). Work in a well-ventilated area, preferably with exhaust fans or open windows to allow fresh air in and toxic fumes out. Using ventilation systems can protect you from harmful vapors that are released during the curing process.

| Ventilation Tip | Description |

|---|---|

| Exhaust Fans | Use exhaust fans to remove fumes |

| Open Windows | Keep windows open for fresh air circulation |

To better understand these precautions, see our section on how to mix epoxy resin.

Personal Protective Equipment (PPE)

When handling epoxy resin, wearing Personal Protective Equipment (PPE) is essential. This includes gloves, masks, and safety goggles to protect your skin, eyes, and lungs from harmful chemicals (Missouri Poison Center).

| Protective Gear | Purpose |

|---|---|

| Gloves | Prevent skin contact |

| Masks | Protect against airborne particles |

| Safety Goggles | Shield eyes from splashes |

For more on safety and preparation, check out is epoxy resin toxic and how to cure epoxy resin.

By following these safety measures, you can significantly reduce the health risks associated with using epoxy resin, ensuring your projects are both beautiful and safe.

Skin Contact with Epoxy Resins

Effects on Skin

Epoxy resins are widely used in various home renovation projects due to their versatility and durability. However, when working with epoxy resins, it is crucial to understand their impact on your skin. Generally, pure epoxy resins are considered non-toxic, but there are significant risks associated with skin contact, especially during the curing process.

Prolonged exposure to epoxy resin can lead to skin irritations, including toxic eczema or allergic contact dermatitis (Nils Malmgren). The hardeners used in epoxy resins often contain aliphatic polyamines, which are particularly irritating to the skin. Even without prolonged exposure, direct contact with epoxy resins can cause redness, itching, and, in severe cases, blistering.

| Effect | Description |

|---|---|

| Redness | Skin appears red and inflamed. |

| Itching | Persistent itching sensation in the affected area. |

| Blistering | Formation of fluid-filled blisters due to severe irritation. |

To safeguard yourself from these effects, it is paramount to wear personal protective equipment (PPE), such as gloves, long sleeves, and a mask.

Treatment for Skin Contact

Accidental contact with epoxy resin requires immediate attention to minimize skin irritation. Here are some essential steps to follow if epoxy resin gets on your skin:

-

Wash the Affected Area: Immediately rinse the area with soap and lukewarm water. The soap helps in breaking down the resin, while lukewarm water ensures no additional irritation occurs. (Missouri Poison Center).

-

Avoid Hot Water: Using hot water can worsen the irritation. Stick to lukewarm or cool water to keep the skin calm.

-

Use a Mild Scrub: If necessary, use a mild scrub to gently remove any remaining resin particles. Avoid rubbing the skin too hard as it can exacerbate irritation.

-

Moisturize: After cleaning, apply a soothing moisturizer or a specialized lotion designed for irritated skin. This helps in maintaining the skin’s hydration and speeds up the healing process.

-

Medical Attention: If the irritation persists or if you develop severe symptoms like blistering, consult a healthcare professional promptly.

For more comprehensive guidance on handling epoxy resin, take a look at our article on how to get epoxy resin off hands.

Following these guidelines can significantly reduce the risks and ensure a safer, more pleasant experience when working with epoxy resins. If you’re curious about more tips and techniques on using epoxy resin, explore our resources on how to use epoxy resin and is epoxy resin toxic.

Inhalation Risks of Epoxy Resins

Epoxy resins are widely used in various home renovation projects, but it’s essential to understand the inhalation risks associated with their use. Breathing in the fumes or dust from epoxy resin can have serious effects on your respiratory system.

Respiratory Irritation

When epoxy resin is mixed with a hardener, it undergoes a chemical reaction that produces heat and releases fumes. These fumes can be irritating to your respiratory system, especially in an unventilated space. According to the Missouri Poison Center, these fumes can cause coughing, shortness of breath, and other irritations.

Inhalation of epoxy vapors can also lead to respiratory sensitization, meaning you’ll become more sensitive to the fumes over time. In severe cases, this can trigger allergic reactions, making it difficult for you to breathe. The WEST SYSTEM points out that inhaling sanding dust from partially cured epoxy can exacerbate these issues, causing even more severe respiratory irritation and allergy symptoms.

To put the risks into perspective:

| Risk | Symptom |

|---|---|

| Inhalation of Epoxy Vapors | Coughing, Shortness of Breath, Respiratory Irritation |

| Sensitization | Allergic Reactions, Increased Sensitivity Over Time |

| Inhalation of Sanding Dust | Severe Respiratory Irritation, Allergic Symptoms |

Precautions for Inhalation

To minimize the risks of inhaling epoxy fumes or dust, there are several precautions you should take:

-

Proper Ventilation: Always work in a well-ventilated area. Use exhaust fans or open windows to ensure that fumes dissipate quickly. For more insights, check out our section on ventilation and respiratory protection.

-

Avoid Spraying: Spraying epoxy is strongly discouraged as it increases the release of hazardous volatile components (WEST SYSTEM). Use other application methods to reduce exposure.

-

Use a Respirator: Invest in a good quality respirator designed for organic vapors. This can significantly reduce your exposure to harmful fumes.

-

Eye Protection: Your eyes can also be affected by epoxy fumes. Wear safety goggles to protect them.

-

Sanding Precautions: When sanding cured epoxy, always wear a dust mask or respirator and ensure the area is well-ventilated. This prevents inhalation of fine particles that can irritate your lungs.

-

Environmental Concerns: Consider using epoxy resins that emit lower levels of volatile organic compounds (VOCs). For example, WEST SYSTEM Epoxy emits significantly fewer VOCs than conventional vinyl ester resins.

For a more comprehensive guide on how to use epoxy safely, refer to our article on how to use epoxy resin.

Best Practices for Resin Disposal

Always follow safe disposal practices for epoxy resin to minimize environmental impact. For step-by-step guidelines, visit our section on disposal and environmental impact.

By following these precautions, you can significantly reduce the inhalation risks associated with epoxy resins, making your home renovation projects safer and more enjoyable.

Disposal and Environmental Impact

Proper disposal and understanding the environmental impact of epoxy resins are critical for ensuring safety and environmental protection. This section will guide you through the safe disposal practices and highlight the main environmental concerns associated with epoxy resins.

Safe Disposal Practices

When dealing with epoxy resin waste, it is essential to follow specific disposal guidelines to prevent hazards and environmental damage. According to WEST SYSTEM, epoxy resins and hardeners are not classified as hazardous wastes in their original form. However, disposal regulations may vary by state and local authorities, so it’s always a good idea to check the local guidelines.

Curing Waste Epoxy Resin

To dispose of waste epoxy resin safely, cure the waste in small quantities until it forms a non-hazardous inert solid. During the curing process, keep pots of curing epoxy in a safe and ventilated area, away from combustible materials, to avoid the risk of fire and hazardous fumes.

| Step | Action |

|---|---|

| 1 | Place epoxy waste in small quantities. |

| 2 | Cure in a ventilated area, away from combustibles. |

| 3 | Wait until the epoxy is fully cured and cooled. |

| 4 | Dispose of the inert solid as non-hazardous waste. |

Refer to the how to dispose of epoxy resin guide for more detailed instructions.

Environmental Concerns

Epoxy resins have a lower volatile organic compound (VOC) emission compared to conventional vinyl ester resins. For example, using 10 gallons of conventional vinyl ester resin emits 30 pounds of VOCs, whereas the same quantity of WEST SYSTEM Epoxy emits only one pound of VOCs (WEST SYSTEM). Despite the lower VOC emission, proper handling and disposal are still necessary.

Long-Term Environmental Impact

Improper disposal of epoxy resins can lead to environmental pollution, affecting water sources, soil health, and wildlife. Follow local, state, and federal guidelines to ensure compliance with environmental regulations. WEST SYSTEM emphasizes identifying and correctly disposing of various hazardous wastes from projects, including paints, gel coats, and solvents, to mitigate environmental harm.

Comparison of VOC Emissions

| Resin Type | VOC Emission (10 gallons) |

|---|---|

| Conventional Vinyl Ester | 30 pounds |

| WEST SYSTEM Epoxy | 1 pound |

For more information on the broader environmental impact and practices, refer to our guides on how to clean epoxy resin and how to remove epoxy resin. Proper disposal and minimal environmental impact should always be a priority when working with epoxy resins.

Types and Applications of Epoxy Resins

Epoxy resin is a versatile material known for its adhesive properties and resistance to chemicals and moisture. Understanding the different types of epoxy resin formulations and their applications helps you utilize this material effectively.

Different Epoxy Resin Formulations

Epoxy resins come in various formulations, each designed for specific uses. Here are the most common types:

-

Two-Part Epoxy Resin: This is the most widely used type, consisting of a resin and a hardener. When mixed, they cure to form a rigid, durable bond. Ideal for DIY projects and woodworking.

-

UV-Resistant Epoxy Resin: Formulated to resist yellowing from UV exposure, perfect for outdoor projects and items exposed to sunlight.

-

Marine Epoxy Resin: Specially designed for underwater repairs and applications, offering excellent moisture resistance.

Here’s a table summarizing these formulations:

| Type | Best for |

|---|---|

| Two-Part Epoxy Resin | General-purpose bonding |

| UV-Resistant Epoxy | Outdoor projects |

| Marine Epoxy Resin | Underwater applications |

Versatile Applications in Various Industries

Epoxy resin finds applications across multiple industries due to its strong adhesive properties and durability:

-

Construction: Used in adhesives, coatings, and laminates. Epoxy resins help in bonding concrete, metal, and other building materials effectively, making them ideal for structural applications (RS Online).

-

Woodworking: Popular for creating river tables, repairing wood, and other woodworking projects. The adhesive can bond wooden surfaces strongly and is often used to create durable and aesthetically pleasing finishes.

-

Manufacturing: Used in the automotive and aerospace industries to create parts and components due to its ability to withstand moderate temperatures and resist chemicals.

-

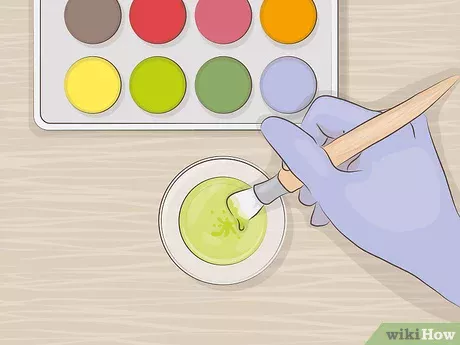

Crafting and DIY: For creating jewelry, art pieces, and home decor items. The versatility of epoxy resin allows for creativity with color and design (how to add color pigment to epoxy resin).

Here’s a look at the variety of applications:

| Industry | Application Examples |

|---|---|

| Construction | Bonding concrete, coatings, repair works |

| Woodworking | River tables, wood repair, sealing wood |

| Manufacturing | Automotive parts, aerospace components |

| Crafting/DIY | Jewelry, art pieces, home decor items |

Epoxy resin’s versatility allows you to explore a wide range of applications and projects. Whether for construction projects, woodworking, or crafting, there’s an epoxy resin suitable for your needs. For more information on how to handle epoxy resin safely, check our guide on how to use epoxy resin.