Is Epoxy Resin Flammable: Safety Concerns

Understanding Epoxy Resin Flammability

Epoxy Resin Basics

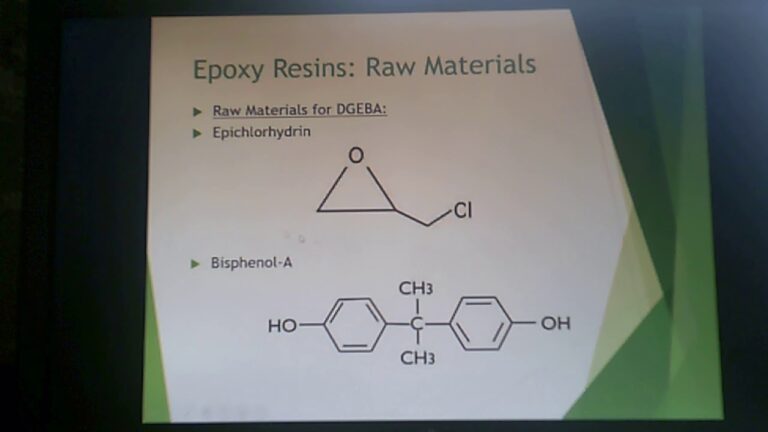

Epoxy resin is a versatile adhesive that is popular for home renovations and various DIY projects. Understanding what epoxy resin is can help you determine how to handle it safely. Most epoxy resins are composed of two parts: the resin and the hardener. When mixed together, they undergo a chemical reaction that creates a hard, durable surface. For detailed information, you can check our guide on what is epoxy resin.

Epoxy resins like the 1980/2000/2020/2040 series are typically 100% solids with no volatile organic compounds (VOCs), making them relatively safe under normal conditions. This means they do not release harmful chemicals into the air during curing.

Flammability Concerns

Although epoxy resin itself poses minimal flammability risks due to its lack of VOCs, it is crucial to know that both the resin and hardener contain easily oxidized organic compounds. These can burn if exposed to fire (Swaylocks Forum). This means while epoxy resin is generally not a fire hazard on its own, it can become flammable in certain conditions.

| Epoxy Resin Attribute | Flammability Risk |

|---|---|

| 100% Solids, No VOCs | Low under normal conditions (Swaylocks Forum) |

| Contains easily oxidized organic compounds | Increased risk when exposed to fire |

Improper mixing or application can also lead to flammability issues. For example, improperly handled epoxy could result in smoking cups of resin or even reach a flashpoint, igniting surrounding elements (Swaylocks Forum). Further information on epoxy safety tips can be found on Entropy Resins.

To mitigate these risks, always ensure proper handling and follow the manufacturer’s instructions carefully. Employing safety measures such as maintaining adequate ventilation and using a heat protectant for hair straightening can further enhance safety.

If you are curious about how to safely mix and cure epoxy resin, be sure to check out our guides on how to mix epoxy resin and how to cure epoxy resin for more details. For proper disposal, you might want to look at our article on safe disposal guidelines.

By understanding the basics and flammability concerns of epoxy resin, you can use this versatile material safely in your home renovation projects.

Factors Influencing Flammability

Understanding the flammability of epoxy resin involves examining various factors that can influence its behavior. Here, we delve into the inclusion of mycelium and the role of additives in epoxy resin.

Inclusion of Mycelium

Mycelium, the root structure of fungi, has been studied for its impact on epoxy resin. Interestingly, the presence of mycelium in epoxy resin coatings can influence flammability in several ways:

- Char Formation: Mycelium enhances char formation, which helps in creating a barrier on the resin surface. This barrier reduces heat transfer and limits the availability of combustion fuel (PMC).

- Thermal Degradation: The inclusion of mycelium in epoxy resin causes a shift in the maximum mass loss temperature toward lower temperatures but does not significantly alter the thermal degradation pathway of neat epoxy.

- Deacetylated Mycelium: Deacetylated mycelium significantly improves char formation due to the presence of chitosan, which enhances thermal stability and char yield.

| Component | Effect on Epoxy Resin | Impact on Flammability |

|---|---|---|

| Unmodified Mycelium | Slight shift in degradation temperature | Moderate char formation |

| Deacetylated Mycelium | Enhanced char formation | Improved thermal stability |

If you’re curious about creating fireproofing coatings or looking into green alternatives, mycelium-containing epoxy resins show promise.

Epoxy Resin Additives

Additives play a crucial role in modifying the properties of epoxy resin, including its flammability:

- Flame Retardants: Certain additives are specifically designed to enhance the flame resistance of epoxy. These are often phosphates or brominated compounds that interrupt the combustion process.

- Plasticizers: While these can improve flexibility, they may also increase flammability. It is essential to choose additives that balance the required mechanical properties with safety.

- Filler Materials: Additives like aluminum trihydrate or magnesium hydroxide decompose endothermically and release water, which helps to cool the material and create a barrier during combustion.

When selecting additives, especially for home renovation projects, it’s crucial to consider their impact on both the performance and safety of the epoxy resin. For more detailed guidelines and application methods, check out our page on how to use epoxy resin.

These factors highlight the importance of a thorough understanding and cautious approach when working with epoxy resin. For additional safety tips and best practices, including proper storage and ventilation, explore our how to mix epoxy resin guide.

Fire Safety with Epoxy Resin

Heating and Curing Risks

When it comes to epoxy resin, understanding the risks associated with heating and curing is crucial. Epoxy cures through an exothermic chemical reaction that generates heat. This reaction can become dangerous if epoxy is left to cure in a contained mass. It can generate enough heat to melt plastic, burn skin, or ignite nearby combustible materials.

The heat generated by curing epoxy resin increases with the size and thickness of the epoxy mass. It is essential to follow the manufacturer’s guidelines on the appropriate curing process and avoid leaving large quantities of mixed epoxy to cure unsupervised. Always work in a well-ventilated area to avoid exposure to toxic vapors such as carbon monoxide, oxides of nitrogen, ammonia, and aldehydes, which are emitted when leftover mixed epoxy thermally decomposes.

Handling Hardener Cautions

Handling hardeners in epoxy resin poses additional safety concerns. The hardener can release toxic fumes, especially when involved in a fire, making it imperative for firefighters to wear appropriate gear to avoid inhaling smoke or vapors (Swaylocks Forum).

When mixing hardeners with materials like sawdust or woodchips, there is a heightened fire hazard. The combination generates heat, and if spilled hardener reacts with cellulose materials, it can ignite combustibles. Avoid using sawdust or similar materials to absorb hardener spills or dispose of unused hardener by pouring it into waste with cellulose materials (Entropy Resins).

Here are some additional precautions for safely handling epoxy resin and hardeners:

- Read and follow all application and safety instructions.

- Use proper mixing procedures to prevent unexpected results.

- Work in well-ventilated areas to reduce exposure to toxic fumes.

- Store and handle materials away from combustible items to prevent fire hazards.

For more information on safely using epoxy resin for your projects, check our guides on what is epoxy resin, how to use epoxy resin, and how to remove epoxy resin. Additionally, explore what are some good polishers for epoxy resin and other related topics for a comprehensive understanding.

Safety Precautions for Home Renovators

When it comes to working with epoxy resin, especially for home renovation projects, understanding and following safety precautions is vital. Here are some essential safety guidelines for you to take into account.

Proper Mixing Procedures

Mixed epoxy resin can start a fire if the resin and hardener mixture gets too hot, causing the mixing cup to melt or catch fire. To prevent this, use a metal container and have a fire extinguisher nearby when working with mixed epoxy resin. Follow these steps for safe mixing:

- Choose the Right Container: Use a metal container to mix resin to prevent the mixing cup from melting.

- Measure Accurately: Ensure you have the correct ratio of resin to hardener, following the manufacturer’s instructions.

- Mix Slowly: Mix slowly and thoroughly to avoid introducing too much air and to control the heat generation.

- Monitor Temperature: Keep an eye on the temperature of the mixture, stopping if it becomes too warm.

For more detailed instructions, you can read our guide on how to mix epoxy resin.

Ventilation and Storage Tips

Proper ventilation and storage are critical when working with epoxy resin to avoid inhaling harmful fumes and prevent fire hazards. Here are some essential tips:

-

Ventilation: Always work in a well-ventilated area. Spraying epoxy poses enormous health and safety risks, as the mist produced is easily inhaled, leading to serious lung damage and other health problems.

-

Protective Gear: Wear a mask, gloves, and protective eyewear to shield yourself from inhaling fumes and to prevent skin contact. This is crucial when dealing with mist and vapors, which can cause skin sensitization and allergic reactions.

-

Storage: Store epoxy resin and hardeners in a cool, dry place away from direct sunlight and heat sources. Leftover mixed epoxy can emit toxic vapors such as carbon monoxide, oxides of nitrogen, ammonia, and aldehydes when it thermally decomposes. Avoid using flames to release casted or embedded objects unless it’s a last resort.

-

Proper Disposal: Dispose of epoxy resin materials according to local regulations. For guidance, check our page on safe disposal guidelines for epoxy resin.

By following these safety precautions, you can effectively minimize the risks involved in using epoxy resin for your renovation projects. For additional resources, consider reading our articles on how to use epoxy resin and how to clean epoxy resin off tools.

Best Practices for Handling Epoxy Resin

Preventing Combustion

Handling epoxy resin safely involves taking steps to prevent combustion. Epoxy cures through an exothermic chemical reaction that produces heat. When epoxy resin is left to cure in a contained mass, it can generate sufficient heat to melt plastic, burn skin, or even ignite nearby materials. The larger or thicker the epoxy mass, the more heat it generates (Entropy Resins).

| Epoxy Part | Potential Risk | Safety Measure |

|---|---|---|

| Mixed Resins | High Heat | Use in thin layers |

| Curing Process | Ignition | Ensure adequate ventilation |

To prevent combustion:

- Avoid mixing large batches of epoxy resin. Instead, mix smaller amounts to reduce heat buildup.

- Use the epoxy resin in thin layers to dissipate heat more effectively.

- Do not leave mixed epoxy in the mixing container for prolonged periods. Transfer it immediately to a working surface.

- Ensure adequate ventilation in the working area to disperse any heat generated during the curing process.

- Keep flammable materials away from the curing area.

For more tips on properly using epoxy resin, visit our guide on how to use epoxy resin.

Safe Disposal Guidelines

Proper disposal of epoxy resin is essential to prevent heat buildup and potential fire hazards. Mixing hardeners with sawdust, wood chips, or other cellulose materials can pose a fire risk, as this combination generates heat. Spilled hardener reacting with cellulose material can ignite combustibles (Entropy Resins).

| Component | Disposal Method | Preventive Action |

|---|---|---|

| Unused Resin | Follow local guidelines | Contact waste management authorities |

| Hardened Resin | Regular trash | Ensure fully cured |

| Leftover Hardener | Do not mix with cellulose | Use absorbent pads if necessary |

Guidelines for safe disposal:

- Do not mix unused hardeners with sawdust or other cellulose materials. This can lead to combustion.

- For small amounts of leftover resin and hardener, allow them to cure fully before disposal. Once cured, epoxy can be disposed of with regular household trash.

- For larger amounts, contact local waste management authorities for guidelines on hazardous waste disposal.

- Clean tools and containers promptly to avoid the buildup of hazardous materials. For tips on cleaning tools, see our article on how to clean epoxy resin off tools.

Following these best practices ensures that you handle and dispose of epoxy resin safely, reducing the risk of combustion and environmental harm. For more information about epoxy resin safety, explore our article on is epoxy resin toxic.