What Is the Strongest JB Weld: Top Choices for Ultimate Strength

When it comes to fixing, bonding, or sealing just about anything, JB Weld stands out as a trusted name in adhesives. But with so many options available, you might wonder, what’s the strongest JB Weld for your specific needs? Whether you’re repairing a cracked engine block or patching up a leaky pipe, choosing the right product is crucial for a durable and long-lasting fix.

In this text, you’ll discover the strongest JB Weld products and how they can handle the toughest jobs. We’ll break down the features and applications of each type, so you can make an well-informed choice and get your repairs done right the first time.

Key Takeaways

- Versatile Applications: JB Weld is suitable for a wide range of materials, including metal, wood, plastic, ceramic, fiberglass, brick, and concrete, making it ideal for multiple types of repairs.

- Top Products: Key JB Weld products include the Original, KwikWeld, and MarineWeld, each offering specific features such as high tensile strength, fast-setting times, and water resistance.

- High Tensile Strength: JB Weld Original boasts a tensile strength of over 5,000 psi, making it one of the strongest options for bonding and repairing heavy-duty materials.

- Proper Usage: For optimal results, ensure surfaces are clean, dry, and properly prepped. Mix the resin and hardener in equal parts and follow the recommended curing times.

- Varied Use Scenarios: Whether for household repairs, automotive fixes, or industrial applications, choosing the right type of JB Weld can lead to long-lasting and durable repairs.

- Environmental Resilience: Products like MarineWeld are designed to withstand harsh conditions, such as continuous water exposure, making them suitable for marine environments.

Understanding JB Weld

JB Weld offers a range of two-part epoxy adhesives, each designed for specific bonding applications. Let’s explore some of the strongest JB Weld products to help you choose the right one for your needs.

Key JB Weld Products and Their Strengths

JB Weld Original

- Tensile Strength: Over 5,000 psi (34.5 MPa)

- Applications: Ideal for bonding metal, wood, plastic, ceramic, fiberglass, brick, and concrete.

- Features: Versatile and strong, making it suitable for various repair tasks.

JB Weld KwikWeld

- Tensile Strength: Similar to JB Weld Original

- Applications: Excellent for bonding metal and other surfaces where a fast-setting option is necessary.

- Features: Quick curing time without compromising on strength, perfect for urgent repairs.

JB Weld MarineWeld

- Tensile Strength: Comparable to JB Weld Original

- Applications: Specifically designed for marine environments, bonding aluminum, composites, and fiberglass.

- Features: Resilient to water exposure, ensuring durable repairs in wet conditions.

Comparative Data for JB Weld Products

| Product | Tensile Strength (psi) | Suitable Materials | Specific Features |

|---|---|---|---|

| JB Weld Original | Over 5,000 | Metal, wood, plastic, ceramic, brick | Highly versatile |

| JB Weld KwikWeld | Similar to Original | Metal, other surfaces | Fast-setting for quick fixes |

| MarineWeld | Comparable to Original | Aluminum, composites, fiberglass | Ideal for marine environments |

- Surface Preparation: Clean and dry surfaces before application to ensure optimal bond strength.

- Mixing Ratio: Mix the two-part epoxy in the recommended ratios for best results.

- Cure Time: Allow enough time for the epoxy to fully cure, which ranges from a few hours to overnight depending on the product.

JB Weld products offer reliable solutions for various repair needs. Understanding their strengths and suitable applications helps you select the right adhesive for effective and lasting repairs.

Factors Determining JB Weld Strength

Understanding what makes JB Weld strong involves examining several key factors. Let’s explore these elements to know how to optimize the strength of your bond.

Material Composition

JB Weld Original

This epoxy consists of two parts: resin and hardener. It forms a chemical bond when mixed, providing a tensile strength of over 5,000 psi (approx. 34.5 MPa).

Surface Preparation

Properly preparing the bonding surface is crucial. Key steps include:

- Cleaning: Remove any dirt, oil, or debris.

- Roughening: Use sandpaper or a file to create a textured surface.

- Maximizing: Increase the surface area for a stronger bond.

Mixing Quality

Accurate mixing of resin and hardener ensures optimal strength. Improper mixing can lead to weak bonds, so follow the recommended ratio and stir thoroughly.

Usage Scenarios

Application Types

The effectiveness of JB Weld can vary depending on its application:

- Metal repair: Ideal for fixing broken metal parts.

- Corrosion holes: Fills gaps caused by rust.

- Multi-material bonding: Suitable for metal, wood, plastic, and fiberglass.

| JB Weld Types | Tensile Strength (psi) | Suitable Materials | Special Features |

|---|---|---|---|

| JB Weld Original | 5,000+ | Metal, wood, fiberglass | Strong, versatile |

| KwikWeld | 2,425 | Metal, wood, plastic | Quick-setting |

| MarineWeld | 3,960 | Metal, fiberglass | Water-resistant |

To achieve the best results, ensure the surface is prepped, mixed correctly, and applied appropriately based on the materials and conditions. This approach maximizes the bond’s strength and longevity.

Comparing JB Weld Products

When choosing the strongest JB Weld products for your repair needs, it’s essential to understand each product’s unique characteristics and applications.

High-Strength Options

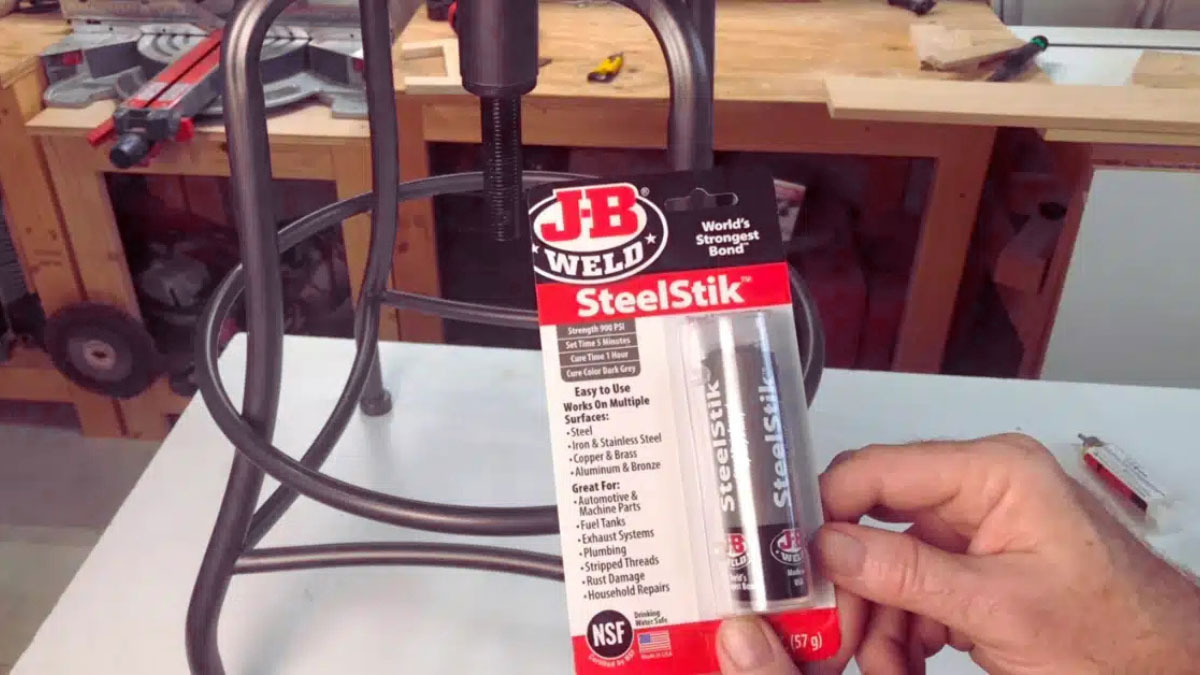

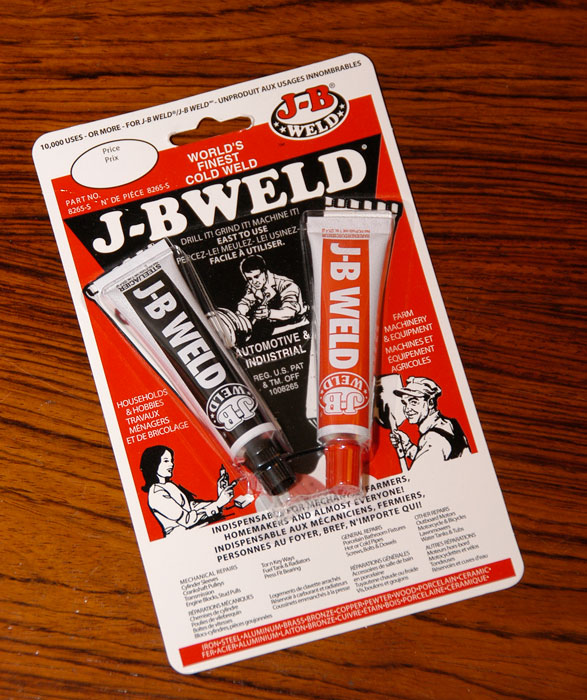

JB Weld Original Cold-Weld (8265-SUK):

- Tensile Strength: Over 5,000 psi (34.5 MPa).

- Components: Two-part epoxy system with resin and hardener.

- Applications: Ideal for metal repairs due to its high-strength bond.

- Example Use: Fixing a cracked engine block or repairing a metal pipe.

JB Weld KwikWeld:

- Tensile Strength: Slightly lower than the original JB Weld.

- Set Time: Faster setting time compared to the original product.

- Applications: Suitable for quick repairs on metal and other surfaces where time is of the essence.

- Example Use: Emergency car repairs or household fixes needing quick action.

Versatile Adhesives

JB Weld Original:

- Versatility: Works well on a variety of materials including metal, wood, plastic, tile, PVC, ceramic, and fiberglass.

- Tensile Strength: As previously mentioned, over 5,000 psi.

- Applications: Multi-purpose, making it a staple for general repair needs.

- Example Use: Bonding dissimilar materials in DIY projects or routine household repairs.

| Product | Tensile Strength | Set Time | Versatility | Example Uses |

|---|---|---|---|---|

| JB Weld Original | 5,000+ psi (34.5 MPa) | 4-6 hours to set, 15-24 hours to cure | Metal, wood, plastic, tile, PVC, ceramic, fiberglass | Engine repairs, household fixes |

| JB Weld KwikWeld | Slightly lower than Original | 6 minutes to set, 4-6 hours to cure | Metal and other surfaces | Urgent car repairs, quick household fixes |

Understanding the specifics of JB Weld products will help you make informed decisions for effective and durable repairs. Choose the right JB Weld product for your specific needs by considering factors like tensile strength, set time, and material compatibility.

How To Use JB Weld Effectively

Proper use of JB Weld is essential to achieve the strongest bond and extend the life of your repairs. Follow these critical steps to ensure optimal results.

Surface Preparation

Ensuring proper surface preparation is key for a secure bond.

- Cleaning: Remove oils, grease, and contaminants from the surfaces. Use a degreaser or soapy water.

- Roughening: Scuff the surfaces with sandpaper to create a texture that the adhesive can grip. Aim for a uniform roughness.

- Drying: Ensure surfaces are completely dry before application, as moisture can weaken the bond.

Mixing Instructions

Accurate mixing determines the quality of the bond.

- Equal Parts: Dispense equal amounts of the resin and hardener. JB Weld products often come with marked containers to help.

- Thorough Mixing: Mix the components until you achieve a consistent color. Use a mixing stick and take about 1-2 minutes.

Application Techniques

Applying the epoxy correctly is crucial for achieving the maximum bond.

- Layering: Apply in a thin layer initially. This helps ensure proper adhesion to the surface.

- Spreading: Spread the mixture evenly over the bonding area. For larger areas, use a putty knife or spreader.

Drying and Curing Time

Adhering to recommended drying and curing times ensures the bond reaches its full strength.

- Setting Time: Initial set time is typically around 4-6 hours. Avoid disturbing the joint during this period.

- Full Cure: Allow 15-24 hours for a complete cure. JB Weld achieves its maximum strength after this period.

Following these steps can help you use JB Weld effectively, ensuring strong and lasting repairs. For specific applications, always check the product-specific instructions.

Real-World Applications

Industrial Uses

JB Weld is widely used in industrial applications due to its high strength and versatility. Here are some common industrial uses:

- Metal Bonding: Frequently used to bond metal parts such as steel and aluminum, JB Weld provides a practical solution when traditional welding isn’t feasible. It’s particularly effective for repairing engine blocks, pipes, and metal machinery.

- Composite Materials: JB Weld can bond various composites, including fiberglass and carbon fiber. This makes it ideal for automotive repairs, aerospace applications, and structural components in industrial equipment.

- High-Temperature Applications: Withstanding temperatures up to 550°F (288°C), JB Weld is suitable for environments that see significant heat. It’s often utilized in automotive exhaust systems and industrial furnaces.

Household Repairs

JB Weld’s reliability extends to everyday household repairs. Here are some typical applications:

- Plumbing Fixes: When faced with a leaky pipe or a cracked basin, JB Weld provides a reliable sealant that can withstand continuous exposure to water and varying temperatures.

- Furniture Repairs: Ideal for mending broken wooden or metal furniture, JB Weld’s high bonding strength ensures durability and longevity.

- Appliance Maintenance: Broken handles, cracked plastic parts, or loose metal components in household appliances can be effectively repaired using JB Weld, restoring functionality without a complete replacement.

Summary Table

| Type of JB Weld | Tensile Strength (psi) | Bonding Applications | Maximum Temperature (°F) |

|---|---|---|---|

| JB Weld Original | 3,960 | Metal, composites | 550 |

| 8265-SUK Cold-Weld | 5,600 | Metal, composites | 550 |

| KwikWeld | 2,425 | General repairs | 300 |

| MarineWeld | 3,960 | Underwater repairs | 300 |

Action Point

Leverage JB Weld’s robust and versatile formulations for both industrial and household repairs to achieve strong, durable, and heat-resistant bonds. Select the appropriate type based on specific use cases to maximize effectiveness.

Conclusion

Choosing the strongest JB Weld product depends on your specific repair needs. Whether you’re dealing with metal repairs, urgent fixes, or marine applications, JB Weld offers a range of solutions tailored to various challenges. By understanding the unique characteristics and applications of products like JB Weld Original, KwikWeld, and MarineWeld, you can make informed decisions to achieve strong and lasting repairs.

Proper surface preparation and accurate mixing are crucial for maximizing bond strength. Adhering to recommended drying and curing times ensures the bond reaches its full potential. Leveraging JB Weld’s robust formulations can help you tackle both industrial and household repairs with confidence, ensuring durability and reliability.

Frequently Asked Questions

Which J-B Weld product is best for metal repairs?

JB Weld Original is ideal for metal repairs due to its high tensile strength of over 5,000 psi. KwikWeld is another good option for urgent fixes, offering a quicker setting time while still providing a strong bond.

Can J-B Weld repair a cracked engine block?

Yes, JB Weld Original is suitable for repairing cracked engine blocks. It provides a durable, heat-resistant bond that can withstand high temperatures and pressures when properly applied.

How long does it take for J-B Weld to cure fully?

The initial set time for J-B Weld is 4-6 hours. However, for a full cure and maximum bond strength, it requires 15-24 hours. Ensure to follow the recommended drying times for the best results.

Is J-B Weld waterproof?

Yes, many JB Weld products are waterproof once fully cured. For specific water-related repairs, consider using MarineWeld or WaterWeld, which are designed for durable performance in wet conditions.

What is the tensile strength of JB Weld Original?

JB Weld Original boasts a tensile strength of over 5,000 psi, making it suitable for a wide range of repair applications, including heavy-duty and high-stress environments.

How should I prepare the surface before applying J-B Weld?

Proper surface preparation involves cleaning, roughening, and drying the surfaces to maximize adhesion. This ensures a strong and lasting bond when applying J-B Weld products.

Can J-B Weld be used on plastic?

Yes, JB Weld products can bond to some plastics, but compatibility depends on the specific plastic type. For the best results on plastics, consider using PlasticWeld specifically formulated for these materials.

Does J-B Weld withstand high temperatures?

Yes, JB Weld products, especially HighHeat and Original, can withstand high temperatures, making them suitable for applications in engines and other high-heat environments.

How long does it take for KwikWeld to set and cure?

KwikWeld sets in about 6 minutes and cures fully within 4-6 hours. This quick setting time makes it ideal for urgent repairs that require fast bonding.

Can J-B Weld bond dissimilar materials?

Yes, JB Weld is versatile and can bond a variety of materials, including metal, wood, plastic, ceramic, and more. This makes it useful for multi-material repairs.