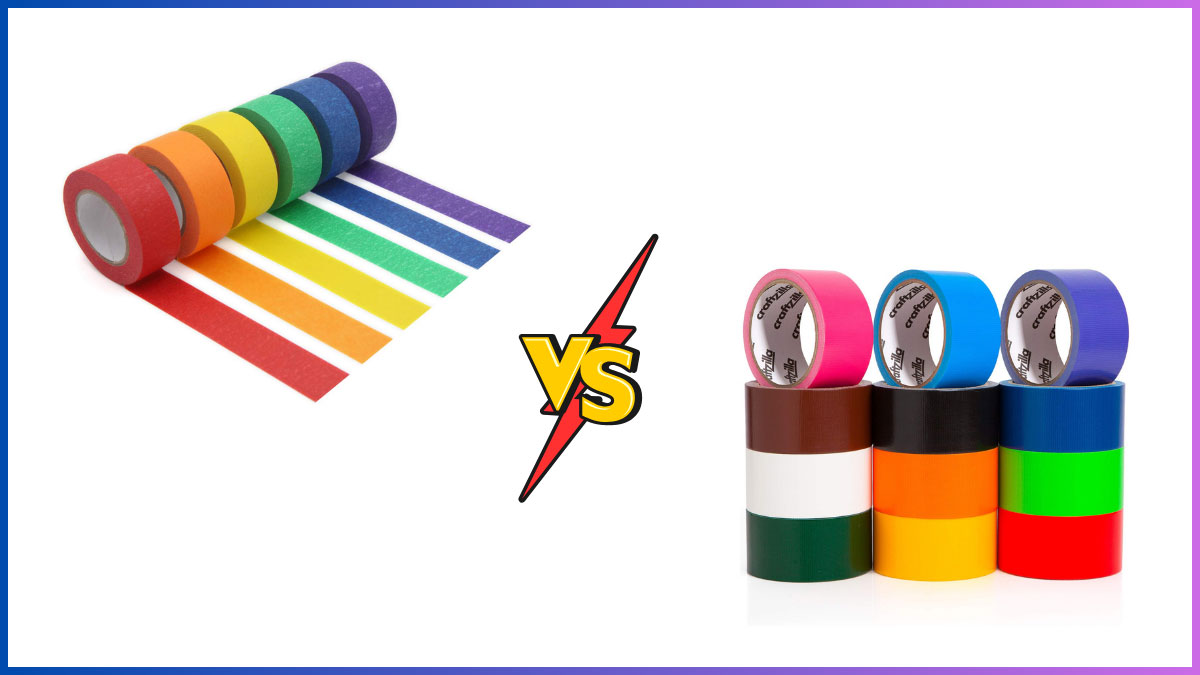

Masking Tape vs Duct Tape: Choosing the Right Tape for Your Project

When you need to tackle a project, choosing the right tape can make all the difference. Masking tape and duct tape might seem similar at first glance, but they each have unique properties that suit different tasks. Understanding these differences can save you time, effort, and frustration.

Masking tape, known for its easy removal and precision, is perfect for painting and delicate surfaces. On the other hand, duct tape’s strength and durability make it ideal for heavy-duty repairs and binding. Knowing when to use each type ensures your projects turn out just the way you want.

Key Takeaways

- Distinct Uses: Masking tape is ideal for painting, labeling, and delicate surface tasks due to its easy removal and light adhesive strength, while duct tape excels in heavy-duty repairs, sealing, and waterproofing thanks to its strong adhesion and durability.

- Material Differences: Masking tape typically has a paper or cloth backing with a mild adhesive, whereas duct tape features a polyethylene-coated cloth scrim with a robust rubber adhesive, offering more strength and flexibility.

- Adhesive Strength: Masking tape provides mild, temporary adhesion suitable for precise applications without leaving residue, while duct tape offers strong, semi-permanent adhesion, capable of sticking to rough and uneven surfaces.

- Durability and Flexibility: Masking tape is moderately durable and flexible for short-term use, while duct tape is highly durable and suitable for long-term, demanding tasks due to its flexibility and resistance to wear.

- Removal and Residue: Masking tape can be easily removed without leaving residue, making it perfect for temporary projects. In contrast, duct tape may leave sticky residue and is harder to remove, which is suitable for more permanent solutions.

- Choosing the Right Tape: Understanding the unique properties of each tape will help you select the right one for your specific project needs, ensuring successful outcomes whether you need precision or strength.

Overview of Masking Tape and Duct Tape

Masking Tape:

- Purpose and Use:

- Primarily for temporary adhesion, masking tape finds its place in painting, labeling, arts and crafts, bundling, and splicing jobs. Masking tape is named painter’s tape due to its extensive use in painting projects. It’s designed to protect surfaces during painting, ensuring clean removal without residue.

- Construction:

- With a paper or cloth backing, masking tape utilizes several adhesives based on application. Painter’s tape, for instance, has a light adhesive for easy removal, leaving no residue. Variants include paper masking tape, cloth masking tape, and PE cloth masking tape, each offering properties like low adhesion and straightforward removal.

Duct Tape:

- Purpose and Use:

- For stronger adhesion, duct tape suits heavy-duty repairs, sealing, and waterproofing tasks. Used commonly in construction, household repairs, and even industrial applications, duct tape offers versatility and durability. Often called duck tape, it serves various strengthening and binding requirements.

- Construction:

- Duct tape has a polyethylene coating over cloth scrim and rubber-based adhesive. This combination provides both strength and flexibility, enabling it to stick to almost any surface, even those with irregularities. Types include general-purpose, industrial-grade, and specialized duct tape, each with distinct strengths and uses.

Table Comparison of Masking Tape and Duct Tape

| Feature | Masking Tape | Duct Tape |

|---|---|---|

| Primary Use | Painting, labeling, crafting | Heavy-duty repairs, sealing |

| Adhesive Strength | Light to medium | High |

| Surface Type | Smooth and delicate surfaces | Rough and irregular surfaces |

| Removal | Easy, leaves no residue | Harder, may leave residue |

| Material | Paper or cloth backing | Polyethylene-coated cloth scrim |

| Special Types | Painter’s tape, PE cloth tape | General purpose, industrial-grade |

- Masking Tape: Ideal for painting and delicate projects due to light adhesive and easy removal.

- Duct Tape: Suitable for repairs and heavy-duty applications with its high adhesion and durability.

Understanding these properties can help you choose the right tape for your specific project needs.

Key Differences Between Masking Tape and Duct Tape

Understanding the key differences between masking tape and duct tape can help you choose the right one for your project. While both tapes serve distinct purposes, their unique properties make them suitable for different applications. Here’s a detailed look at their characteristics.

Material Composition

- Masking Tape: Made with paper or thin plastic backing, often paired with a mild adhesive. Variations include:

- Paper Masking Tape: Ideal for painting and crafting projects, allowing clean removal without residue.

- Cloth Masking Tape: A niche variant with a low-adhesion cloth backing, designed to minimize residue.

- Duct Tape: Composed of multiple layers:

- Polyethylene Film: Provides waterproofing capabilities.

- Cloth Backing: Usually spun rayon, offers flexibility and tear resistance.

- Rubber Pressure-Sensitive Adhesive (PSA): Ensures strong, semi-permanent bonds.

Adhesive Strength

- Masking Tape: Features a mild adhesive:

- Designed for temporary adhesion.

- Removes cleanly, making it suitable for delicate surfaces.

- Examples: masking walls for painting, labeling items in crafts.

- Duct Tape: Employs a robust rubber adhesive:

- Suitable for permanent and semi-permanent bonds.

- Sticks well to various surfaces, including rough ones.

- Examples: patching a hole, bundling materials together, waterproofing tasks.

Durability and Flexibility

- Masking Tape: Known for:

- Moderate durability, can withstand light wear.

- Flexibility in application but less resistant to heavy stress.

- Ideal for short-term use.

- Duct Tape: Recognized for:

- High durability, able to endure heavy-duty use.

- Excellent flexibility due to the cloth backing.

- Long-lasting performance in demanding environments.

Application Uses

- Masking Tape: Best suited for:

- Painting and Crafting: Allows precise application without damaging surfaces.

- Labeling: Easy to write on and remove.

- General Light Tasks: Quick fixes that don’t require strong adhesion.

- Duct Tape: Adaptable to:

- Repairs: Fixing leaks, sealing gaps, and bundling items.

- Construction and Manufacturing: Provides a strong hold on materials.

- Outdoor Tasks: Resilient in various weather conditions.

| Feature | Masking Tape | Duct Tape |

|---|---|---|

| Material Composition | Paper or thin plastic backing with mild adhesive | Polyethylene film, cloth backing, rubber adhesive |

| Adhesive Strength | Mild, temporary adhesion | Strong, semi-permanent adhesion |

| Durability | Moderate, short-term use | High, long-term use |

| Flexibility | Flexible but light durability | Highly flexible and durable |

| Primary Applications | Painting, crafting, labeling, light tasks | Repairs, construction, manufacturing, outdoor tasks |

| Removal Ease | Clean removal, no residue | Difficult removal, may leave residue |

Choosing between masking tape and duct tape depends on your specific needs. Masking tape’s clean removal and delicate surface compatibility make it indispensable for artistic and precision tasks. Duct tape’s strength and durability make it ideal for extensive repairs and heavy-duty applications.

Advantages and Disadvantages

Choosing between masking tape and duct tape can be critical, depending on the task at hand. Each tape has its own set of benefits and drawbacks. Understanding these can guide you in making the right choice for your project.

Pros and Cons of Masking Tape

Pros:

- Temporary Adhesion: Masking tape applies easily and removes cleanly, ideal for projects needing non-permanent solutions.

- Clean Removal: It’s designed to leave clean lines and comes off effortlessly, ensuring no damage to surfaces.

- Visibility: Often easier to see and mark on, masking tape is great for painting and crafting tasks.

- Variety of Uses: It finds applications in packaging, labeling, arts, crafts, and bundling.

Cons:

- Limited Strength: The lack of heavy-duty strength makes it unsuitable for tasks requiring robust adhesion.

- Adhesion Issues: Some cheaper variants might lack sticky reliability, compromising certain projects.

Pros and Cons of Duct Tape

Pros:

- High Strength: Duct tape’s robust adhesion makes it ideal for heavy-duty repairs and fixes.

- Durability: Its strength and flexibility ensure long-lasting hold for various surfaces, including rough and uneven ones.

- Waterproof: With a polyethylene coating over cloth scrim, duct tape is excellent for waterproofing tasks.

- Versatile Uses: It excels in construction, automotive repair, and other heavy-duty applications, proving its versatility.

- Residue: Duct tape often leaves sticky residue, which can be tough to remove from surfaces.

- Difficult Removal: Strong adhesion can make removing duct tape challenging, potentially damaging delicate surfaces.

Here is a summary table to encapsulate key differences and applications:

| Feature | Masking Tape | Duct Tape |

|---|---|---|

| Adhesive Strength | Light | High |

| Removal | Easy, no residue | Difficult, can leave residue |

| Durability | Moderate, for temporary tasks | High, for permanent repairs |

| Waterproof | No | Yes |

| Flexibility | Limited | Flexible for uneven surfaces |

| Common Uses | Painting, labeling, arts, bundling | Heavy-duty repair, sealing, waterproofing |

This comparison can help you decide on the most appropriate tape for your specific needs, ensuring successful project outcomes.

Choosing the Right Tape for Your Needs

Selecting the correct tape for a project can make a significant difference in the outcome. Masking tape and duct tape serve distinct purposes, and understanding their best uses will guide your decision-making process.

Best Uses for Masking Tape

Masking tape is ideal for projects needing precision and clean removal.

Characteristics:

- Adhesion Strength: Light, providing easy removal.

- Material: Typically made from paper or a thin cloth.

- Surface Compatibility: Works well on delicate surfaces.

Common Applications:

- Painting: Use masking tape to create sharp paint lines. Its low-tack adhesive ensures it won’t damage surfaces.

- Labeling: Effective for temporary labels due to its writable surface.

- Arts and Crafts: Provides flexibility for various DIY projects without damaging materials.

Advantages:

- Clean Removal: Leaves no residue, ideal for temporary applications.

- Precision: Allows for detailed work where accuracy is critical.

Best Uses for Duct Tape

Duct tape excels in demanding situations requiring robust adhesion and durability.

Characteristics:

- Adhesion Strength: High, offering strong, long-lasting stickiness.

- Material: Constructed with a polyethylene coating over a cloth scrim.

- Surface Compatibility: Adheres well to rough and uneven surfaces.

Common Applications:

- Heavy-Duty Repairs: Suitable for fixing leaks, patching holes, and reinforcing objects.

- Sealing: Effective for sealing packages, ducts, and hoses.

- Outdoor Tasks: Weather-resistant, making it suitable for outdoor use.

- Durability: Resistant to water, UV rays, and temperature fluctuations.

- Versatility: Handles a wide range of tasks, from repairs to craft projects.

Understanding these key differences ensures you choose the tape that fits your specific needs, enhancing project success.

| Feature | Masking Tape | Duct Tape |

|---|---|---|

| Adhesion Strength | Light, easy removal | High, robust and long-lasting |

| Material | Paper or thin cloth | Polyethylene coating over cloth scrim |

| Surface Compatibility | Gentle on delicate surfaces | Adheres well to rough and uneven surfaces |

| Common Applications | Painting, labeling, arts and crafts | Heavy-duty repairs, sealing, outdoor tasks |

| Removal | Clean, leaves no residue | May leave sticky residue, hard to remove |

| Durability | Moderate, for temporary tasks | High, suitable for permanent repairs |

Each type of tape serves distinct purposes. Assess your project’s requirements to decide between masking tape and duct tape for optimal results.

Conclusion

Choosing between masking tape and duct tape hinges on your project’s specific needs. Masking tape is perfect for tasks requiring precision and easy removal, like painting and labeling. Its mild adhesive and clean removal make it a go-to for delicate surfaces.

On the other hand, duct tape’s robust strength and durability make it ideal for heavy-duty repairs and outdoor applications. Its strong adhesive and waterproofing capabilities ensure it holds up in demanding conditions.

By understanding the distinct advantages and limitations of each tape, you can make informed decisions that lead to successful project outcomes. Whether you need temporary adhesion or a permanent fix, selecting the right tape is crucial for achieving the best results.

Frequently Asked Questions

What is the primary difference between masking tape and duct tape?

Masking tape is designed for temporary tasks with easy removal and precision, making it ideal for painting and delicate surfaces. Duct tape, on the other hand, is suited for heavy-duty repairs due to its strong adhesive and durability.

Can masking tape be used for heavy-duty repairs?

No, masking tape is not suitable for heavy-duty repairs. It is designed for temporary tasks and easy removal, whereas duct tape is engineered for strong adhesion and durability required for more demanding tasks.

Why is duct tape considered more durable than masking tape?

Duct tape features a polyethylene coating over cloth scrim, enhancing its strength and flexibility. This robust construction makes it ideal for heavy-duty repairs, sealing, and waterproofing tasks.

Is masking tape easy to remove?

Yes, masking tape is designed for clean and easy removal. It has a light adhesive that ensures it doesn’t leave residue, making it perfect for precision tasks such as painting and labeling.

Can duct tape be used on delicate surfaces?

Duct tape is not recommended for delicate surfaces because its strong adhesive can leave residue and potentially damage the surface upon removal. Masking tape is a better option for such applications.

What are the main uses of masking tape?

Masking tape is primarily used for painting, labeling, and arts and crafts. It is also useful for tasks that require temporary adhesion, such as protecting surfaces during cutting or supporting glued items as they dry.

What are the advantages of using duct tape?

Duct tape offers high strength, durability, and waterproofing capabilities. It is versatile for heavy-duty applications and can handle outdoor tasks and permanent repairs effectively.

Are there any disadvantages to using masking tape?

Masking tape lacks the heavy-duty strength needed for more demanding tasks. Additionally, cheaper variants might have adhesion issues, making the tape less reliable for certain applications.

What situations are best suited for using duct tape?

Duct tape excels in demanding situations that require robust adhesion, such as heavy-duty repairs, sealing, and outdoor tasks where strength and durability are critical.