Loctite 248 vs 243: Choosing the Right Threadlocker

When it comes to securing threaded fasteners, Loctite offers a range of products, but choosing the right one can be tricky. Two popular options, Loctite 248 and 243, often come up in discussions about threadlocking solutions. Understanding their differences can save you time and ensure your projects hold up under stress.

Loctite 248 and 243 both promise reliable performance, but they cater to slightly different needs. Whether you’re dealing with maintenance in a high-vibration environment or seeking a medium-strength threadlocker for general use, knowing which product to use is crucial. Let’s jump into the specifics to help you make an informed choice.

Key Takeaways

- Application Needs: Loctite 243 is a versatile liquid threadlocker suitable for general use and applications requiring higher torque and oil resistance. Loctite 248, in stick form, is ideal for precise applications in high-vibration environments.

- Form and Convenience: Loctite 243 comes as a liquid adhesive, while Loctite 248 is available in a stick form, facilitating cleaner and more precise application.

- Strength and Removability: Both are medium-strength threadlockers, but Loctite 243 has a higher breakaway torque (26 Nm) compared to Loctite 248 (17 Nm), affecting ease of disassembly.

- Oil Tolerance: Loctite 243 offers higher oil tolerance, making it more suitable for fasteners exposed to lubricants or mild contaminants. Loctite 248 performs reliably but is less tolerant of contaminants.

- Temperature Resistance: Loctite 243 withstands higher temperatures (up to 360°F) compared to Loctite 248 (up to 300°F), offering greater durability in high-temperature conditions.

- Ideal Applications: Choose Loctite 243 for general applications in automotive and machinery maintenance. Opt for Loctite 248 for high-vibration environments like aerospace, where precision and cleanliness are critical.

Understanding Threadlockers

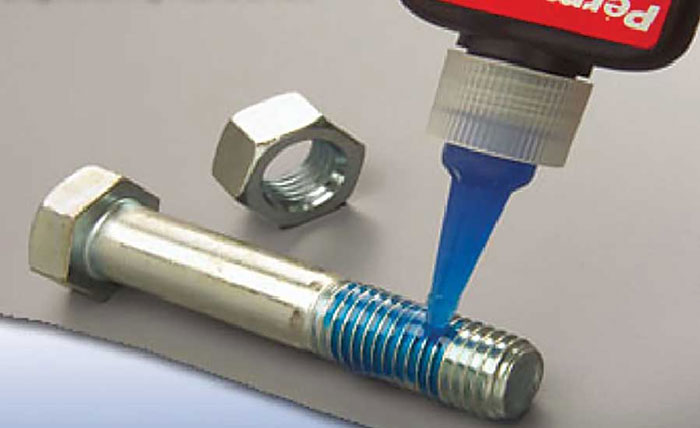

Threadlockers are essential in maintaining the integrity of mechanical assemblies. These liquid adhesives, applied to threaded fasteners, prevent loosening due to vibration, shock, or thermal expansion. They are critical in applications where the stability and security of bolts and screws are paramount.

Importance of Threadlockers

- Prevent Loosening:

Threadlockers secure threaded fasteners, preventing them from loosening over time, especially in high-vibration environments like automotive or industrial machinery. - Sealing:

By filling the gaps between threads, threadlockers help seal connections and prevent the leakage of fluids and gases. - Corrosion Protection:

Some threadlockers offer corrosion protection by creating a barrier against moisture and contaminants that can lead to rust.

Different Threadlocker Types and Their Uses

- Loctite 243:

- Type: Medium strength, removable blue threadlocker

- Uses: Suitable for applications where fasteners may need periodic disassembly without the risk of loosening due to vibration or shock.

- Loctite 248:

- Type: Medium strength, removable stick form threadlocker

- Uses: Convenient for applications requiring precise, clean application. Ideal for high-vibration environments, such as automotive and heavy machinery, where liquid adhesives may spread unevenly.

| Feature | Loctite 243 | Loctite 248 |

|---|---|---|

| Form | Liquid adhesive | Stick form adhesive |

| Strength Level | Medium | Medium |

| Removability | Removable | Removable |

| Application Method | Applied as a liquid to the threads | Applied by rubbing stick on threads |

| Best For | General use, periodic disassembly | Precise application, high-vibration environments |

| Color | Blue | Blue |

Understanding the right type of threadlocker for your application is crucial. Loctite 243 is versatile for general use, while Loctite 248 offers precision and cleanliness, especially in high-vibration scenarios. Consider these options based on the specific needs of your project to ensure the reliability and safety of your mechanical assemblies.

Overview of Loctite 248

Loctite 248 is a medium-strength threadlocker designed for versatility and convenience. It ensures reliable performance in various applications, especially where disassembly might be necessary.

Key Features of Loctite 248

- Medium Strength: Balances locking capability with ease of disassembly, making it ideal when future removal is anticipated.

- Stick Form: The convenient stick form allows precise application, reducing mess and ensuring the product is placed exactly where needed.

- Lower Breakaway Torque: With a breakaway torque of 17Nm, it’s easier to disassemble compared to Loctite 243.

- Removable: Can be taken apart with high torque, and even more easily with special chemicals or heat.

Advantages and Disadvantages of Loctite 248

Advantages:

- Convenience: The stick form allows for easy and precise application.

- Medium Strength: Provides balance between securing fasteners and future disassembly.

- Less Mess: The stick form minimizes spills and waste.

- Removability: Easier to remove with less torque than other threadlockers.

- Lower Torque: Its lower breakaway torque might not be suitable for extremely high-stress applications.

- Form Factor: Some users may prefer liquid over stick forms for certain applications.

- Special Tools for Removal: Although removable, it may still require special chemicals or heat in certain conditions.

Summarizing, Loctite 248 offers a reliable medium-strength solution in a user-friendly stick form, ideal for applications requiring future disassembly.

Overview of Loctite 243

Loctite 243 is a versatile, medium-strength threadlocker designed for general use. It offers a balance between locking power and ease of removal, making it suitable for various applications.

Key Features of Loctite 243

- Medium Strength: Balances locking power and removability, making it ideal for general applications.

- Removable: Disassembles with high torque, heat, or special chemicals.

- Oil Tolerant: Cures on fasteners with minor surface contaminations from cutting, lubrication, anti-corrosion, and protection fluids.

- Primerless: Works effectively without a primer on active and inactive metals, including stainless steel and plated surfaces.

- Temperature Resistance: Withstands temperatures up to 360°F, providing durability in high-temperature environments.

Advantages and Disadvantages of Loctite 243

Advantages:

- Versatile Use: Suitable for general applications, offering a balance of strength and removability.

- Ease of Application: No primer required, saving time and effort.

- Temperature Tolerance: Performs well in temperatures up to 360°F, ensuring reliability in various conditions.

- Contamination Resistance: Effective even on slightly contaminated surfaces, enhancing convenience.

Disadvantages:

- Medium Strength Limitation: May not be suitable for extremely high-stress applications, requiring a stronger adhesive.

- Removal Process: While removable, it may require special chemicals or heat, adding complexity to the disassembly process.

When choosing between Loctite 248 and 243, consider the specific requirements of your project. Loctite 243 excels in general applications, offering reliable performance with ease of removal and contamination resistance.

Comparing Loctite 248 and 243

Understanding the differences between Loctite 248 and 243 helps determine the best fit for your project. Both provide secure fastening but excel in different conditions and applications.

Application Strength and Durability

- Loctite 243: This medium-strength, primerless threadlocker offers a breakaway torque of about 26 Nm (225 in-lbs). Ideal for applications needing higher torque, it maintains its hold under stress.

- Loctite 248: This stick-form threadlocker delivers a lower breakaway torque of approximately 17 Nm. It’s beneficial for applications requiring easier disassembly while still providing secure fastening.

Compatibility with Different Materials

- Loctite 243: Effective on both active and inactive metals, including stainless steel and plated surfaces. Its tolerance for minor surface contaminations, like oils, makes it suitable for diverse environments.

- Loctite 248: Also a medium-strength threadlocker, it works well on various metals. But, its oil tolerance isn’t as high as that of Loctite 243. The stick form offers advantages for overhead and pre-dispensed applications.

| Parameter | Loctite 243 | Loctite 248 |

|---|---|---|

| Strength | Medium | Medium |

| Form | Liquid | Stick |

| Breakaway Torque | 26 Nm | 17 Nm |

| Oil Tolerance | High | Moderate |

| Metal Compatibility | Active and Inactive | Various Metals |

| Application Convenience | General Use | Overhead/Pre-dispensed |

| Temperature Resistance | Up to 360°F | Up to 300°F |

- Loctite 243: Its high oil tolerance and compatibility with different metals make it versatile for industrial and automotive environments.

- Loctite 248: The stick form enhances precision and convenience, making it ideal for applications needing specific and consistent application, like machinery maintenance in high-vibration environments.

Choosing between Loctite 248 and 243 depends on your project’s specific needs, whether you require higher torque, better oil tolerance, or precise application.

Choosing Between Loctite 248 and 243

Understanding the differences between Loctite 248 and 243 is crucial for selecting the right product for your project’s needs. These two medium-strength, removable threadlockers each offer unique benefits suited to different applications.

Factors to Consider

Adhesion Strength and Removability:

- Loctite 243: Boasts a higher breakaway torque of 26 Nm. It’s suitable for high torque applications and can be disassembled using high torque, special chemicals, or heat.

- Loctite 248: Offers a breakaway torque of 17 Nm, making it easier to disassemble. Its stick form provides convenience for precise applications.

Oil Tolerance:

- Loctite 243: Exhibits high oil tolerance, enabling it to cure on fasteners with minor surface contamination. It is ideal for environments where fasteners encounter various oils or chemicals.

- Loctite 248: While it ensures reliable performance, it doesn’t match the oil tolerance level of Loctite 243. Suitable for cleaner, more controlled environments.

Specific Use Case Scenarios

General Applications:

- Loctite 243: Its versatility and durability make it perfect for automotive, machinery, and general maintenance tasks. It can withstand temperatures up to 360°F and works effectively on both active and inactive metals.

High-Vibration Environments:

- Loctite 248: Designed for applications in high-vibration environments, such as aerospace or racing. The stick form aids in precise application, crucial for such demanding conditions.

| Feature | Loctite 243 | Loctite 248 |

|---|---|---|

| Breakaway Torque | 26 Nm | 17 Nm |

| Form | Liquid | Stick |

| Oil Tolerance | High | Moderate |

| Temperature Resistance | Up to 360°F (182°C) | Moderate |

| Removal Method | High torque, chemicals, or heat | High torque, special chemicals |

| Ideal Applications | Automotive, machinery | High-vibration environments |

| Compatibility | Active and inactive metals | Active metals |

Choose the product that aligns with your specific project requirements. Opt for Loctite 243 for applications needing higher torque and oil resistance. If precision and ease of application are critical, go with Loctite 248.

Conclusion

Choosing between Loctite 248 and 243 depends on your specific project needs. Loctite 243 is versatile and oil-tolerant, making it ideal for general applications like automotive and machinery. Its higher breakaway torque provides strong locking power while still allowing for removal when necessary.

On the other hand, Loctite 248’s stick form offers precision and convenience, especially in high-vibration environments such as aerospace or racing. Its lower breakaway torque ensures easier disassembly, perfect for applications where future adjustments are anticipated.

By understanding the unique strengths of each product, you can make an well-informed choice that ensures the integrity and reliability of your mechanical assemblies. Choose the threadlocker that best aligns with your project requirements for optimal performance.

Frequently Asked Questions

What is Loctite 248 used for?

Loctite 248 is a medium-strength threadlocker in a convenient stick form. It is ideal for all metal threaded assemblies, securing bolts, nuts, and studs to prevent loosening due to vibration, especially in high-vibration environments.

Is Loctite 248 stronger than 243?

No, Loctite 243 has a stronger bond with a higher breakaway torque of approximately 26 Nm, compared to Loctite 248’s 17 Nm. Loctite 243 is more suitable for higher torque applications, while Loctite 248 is easier to disassemble.

What is the primary difference between Loctite 243 and 248?

The main difference lies in their form and strength. Loctite 243 is a liquid with higher oil tolerance and stronger adhesion, ideal for general applications. Loctite 248 is a semi-solid stick, providing precise application and ease of use, particularly in high-vibration environments.

Is Loctite 248 oil resistant?

Yes, Loctite 248 is oil-tolerant, making it effective in various general-purpose applications, even in environments where oil contamination is a concern.

Why is Loctite 243 so popular?

Loctite 243 is popular due to its versatility, oil tolerance, and higher temperature resistance up to 360°F. It is suitable for a wide range of general applications, including automotive and machinery.

Can Loctite 243 and 248 be removed?

Yes, both Loctite 243 and 248 are removable. Loctite 243 may require special chemicals or heat for removal, while Loctite 248 can be disassembled with high torque or special chemicals for easier removal.