Does JB Weld Work on Glass: Insights and Tips for Repairs

When it comes to repairing glass, finding the right adhesive can be a challenge. You might have heard of JB Weld, a popular epoxy adhesive known for its strength and versatility. But does it work on glass? Whether you’re fixing a broken window, a cracked mirror, or a cherished piece of glassware, knowing if JB Weld can handle the job is crucial.

In this text, we’ll explore the effectiveness of JB Weld on glass surfaces. You’ll discover its capabilities, limitations, and some tips for achieving the best results. Let’s jump into whether this renowned adhesive can truly mend your glass items and save you time and money.

Key Takeaways

- Limited Effectiveness: JB Weld generally performs poorly on glass surfaces, resulting in weak bonds that are prone to failure. It’s better suited for materials like metal, wood, and ceramics.

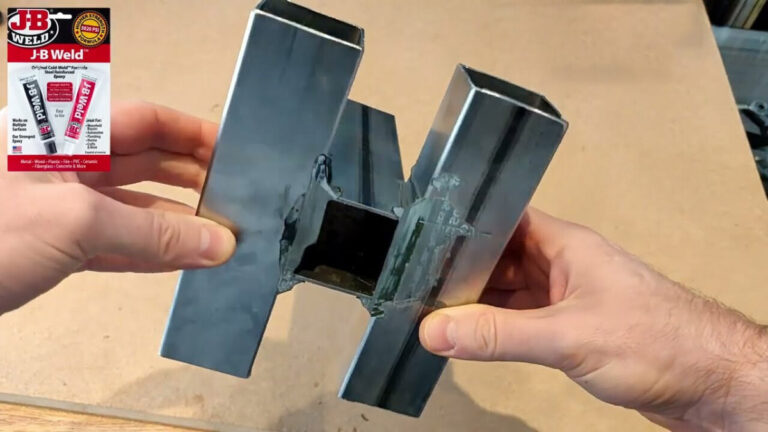

- Product Types: Various JB Weld products exist, but none are specifically designed for glass, including the Standard JB Weld, J-B KwikWeld, J-B WaterWeld, and J-B ClearWeld.

- Surface Preparation Crucial: Thorough cleaning and roughening of the glass surface are essential for better adhesion, though the bond may still be weak.

- Alternative Adhesives Recommended: For reliable, strong, and clear bonds on glass, use adhesives designed specifically for glass such as specialized glass epoxy or silicone adhesives.

- Curing and Drying Time: Understanding and adhering to curing and drying time is crucial if you still choose to use JB Weld, though it’s not ideal for glass applications.

- Durability Concerns: JB Weld’s bonds on glass are typically not durable, especially under environmental stress or changes. Consider alternatives for long-lasting repairs.

Suitability For Glass

Determining if JB Weld is suitable for glass requires understanding its bonding capabilities. Generally, JB Weld is not ideal for glass surfaces due to weak adhesion, resulting in unreliable bonds. Even though some users have tried it, results are often unsatisfactory.

Types Of J-B Weld Products

Various JB Weld products cater to different materials and applications. Here’s a breakdown:

- Standard JB Weld: Commonly used for bonding metals and other materials, not specifically designed for glass.

- J-B KwikWeld: A fast-setting version of the standard product, still not tailored for glass.

- J-B WaterWeld: Specifically for underwater applications, unsuitable for glass bonding.

- J-B ClearWeld: Clear epoxy that may offer better visual appeal for some projects but lacks strong adhesion to glass.

Key Considerations

Several factors affect the success of using JB Weld on glass. Consider these key points:

- Surface Preparation: Glass surfaces require thorough cleaning and roughening to improve adhesion. But, even with preparation, the bond may not be strong.

- Stress Factors: Glass is brittle and subject to stress. JB Weld’s rigidity may cause the glass to crack under stress.

- Alternative Adhesives: For better results, use adhesives designed for glass, such as specialized glass epoxy or silicone adhesives.

| Product | Material Compatibility | Setting Time | Strength (psi) | Clear Finish |

|---|---|---|---|---|

| Standard JB Weld | Metal, wood, stone | 4-6 hours | Up to 5020 psi | No |

| J-B KwikWeld | Metal, ceramics, fiberglass | 4 minutes | Up to 2424 psi | No |

| J-B WaterWeld | Underwater materials | 25 minutes | Up to 900 psi | No |

| J-B ClearWeld | Metal, glass, ceramics | 1 hour | Up to 3900 psi | Yes |

Action Point: For glass repair, rely on materials designed specifically for glass bonding to achieve reliable, strong, and clear bonds.

Preparation Steps

To achieve optimal results in glass repairs, regardless of the adhesive used, preparation is crucial. Effective preparation enhances adhesion and increases the longevity of the repair.

Cleaning the Glass Surface

Cleaning is the first step in ensuring a reliable bond between the adhesive and the glass. To prepare the glass surface properly, follow these steps:

- Remove Contaminants:

- Solution: Use a mild detergent mixed with water.

- Action: Wipe the glass surface thoroughly.

- Focus: Ensure all dirt, oils, and debris are eliminated.

- Rinse and Dry:

- Solution: Plain water.

- Action: Rinse the surface to remove any detergent residue.

- Focus: Dry the glass completely using a lint-free cloth.

- Enhance Adhesion:

- Tool: Fine-grit sandpaper.

- Action: Lightly scuff the area where the adhesive will be applied.

- Focus: Create a slightly rough surface for better grip.

Assembling Necessary Tools

Before starting the repair, gather all necessary tools. Proper preparation ensures a smoother repair process.

- Cleaning Supplies:

- Mild detergent

- Lint-free cloths

- Fine-grit sandpaper

- Safety Equipment:

- Safety gloves

- Safety goggles

- Application Tools:

- Squeegees or applicator brushes (specific to adhesive type)

- Adhesives:

- Specialized glass adhesive (e.g., glass epoxy, silicone adhesive)

Summary Action Point

Correct preparation of glass surfaces and assembling the right tools and materials are essential for effective and lasting glass repairs. By following these structured steps, you ensure stronger adhesion and a more reliable repair.

Application Process

JB Weld can be used on glass, but proper steps enhance effectiveness. Pay attention to surface preparation and application techniques to ensure a strong bond.

Cleaning

Cleaning the surface: Thoroughly clean the glass surface. Use a razor blade to remove old tape or debris and then wipe the area with alcohol to eliminate contaminants.

Surface Preparation

Scuffing the glass: Lightly scuff the glass surface to improve the bond. This step creates a better mechanical interface between the glass and the adhesive.

Mixing The Products

Follow these steps to mix JB Weld properly:

- Read the Instructions: Follow the instructions on the JB Weld package.

- Combine the Epoxy: Mix the two-part epoxy according to the guidelines.

- Ensure Homogeneity: Confirm the mixture is well combined before application.

- Apply Epoxy: Spread the mixed epoxy on the prepared glass surface.

- Use a Toothpick: For small gaps or cracks, use a toothpick to apply the epoxy, ensuring it fills the gap effectively.

Curing And Drying Time

Understanding the curing and drying time for JB Weld helps achieve optimal results in your repair projects. Although JB Weld is not ideal for glass, if you still choose to use it, comprehending the timeframe for setting and curing is crucial.

Setting Time

- Initial Setting: JB Weld typically sets within 4-6 hours.

- Handling Time: It’s advisable to handle the bonded items after this initial setting period, but with caution.

Full Cure

- Complete Curing: The adhesive takes around 24 hours to fully cure and reach maximum strength.

- Environmental Factors: Temperature and humidity can affect the curing time. Warmer conditions usually accelerate the process, while cooler conditions slow it down.

Steps for Monitoring Curing Process

- Check Initial Bond: Inspect the bond after 4-6 hours to ensure the components are holding.

- Wait for Full Cure: Allow a full 24-hour period to ensure the joint reaches its optimal strength.

- Assess Stability: Post-curing, evaluate the stability and durability of the bond under normal usage conditions.

Curing Time Information Table

| Aspect | Duration | Details |

|---|---|---|

| Initial Setting | 4-6 hours | Handle with care after this period |

| Full Cure | 24 hours | Ensure maximum strength by waiting this duration |

| Environmental Impact | Variable | Warmer conditions speed up curing, cooler ones slow it down |

Action Point

To ensure a successful bond using JB Weld on glass, strictly adhere to the curing and drying timelines. This attention to detail enhances the bond’s reliability and longevity, even if JB Weld isn’t the most ideal adhesive for glass applications.

Effectiveness And Durability

JB Weld’s bond strength on glass surfaces is a critical factor to consider. Although this epoxy adhesive excels with metals, ceramics, and wood, its performance on glass remains subpar. If seeking a robust and long-lasting repair on glass, it’s advisable to explore other options.

Key Evaluation Points

- Adhesion to Glass: JB Weld’s adhesion on glass surfaces is limited, leading to weak bonds prone to failure. This deficiency generally results from the smoother, non-porous nature of glass, which reduces effective bonding areas.

- Durability: Instances of JB Weld usage on glass often show poor durability over time. Environmental factors like temperature changes and moisture can further degrade the bond, making it unreliable for long-term repairs on glass items.

Alternative Adhesives

To achieve effective glass-to-glass connections, consider using adhesives designed specifically for this purpose. Here are some alternatives:

- Polyurethane Adhesives: Known for flexibility and strong adhesion, suitable for various glass repairs.

- Silicone Adhesives: Provide excellent waterproof bonds, ideal for aquariums and bathroom glass.

- Specialized Glass Epoxy: Formulated specifically for glass, offering superior bonding strength and clarity.

Practical Considerations

JB Weld might appeal as a versatile adhesive, but when applied to glass, results often fall short, especially in demanding environments. For instance, repairs on windows or glass cookware should avoid JB Weld due to potential health concerns and heat degradation.

Summary Action Point

When repairing glass items, opt for adhesives explicitly designed for glass to ensure strong, durable bonds capable of withstanding environmental stressors. JB Weld, while exceptional for numerous materials, performs poorly on glass, making alternatives a better choice for reliable repairs.

Conclusion

While JB Weld is a versatile adhesive for many materials, it’s not the best choice for glass repairs. Its weak adhesion and poor durability make it unreliable for long-term fixes. For effective and lasting glass repairs, it’s crucial to use adhesives specifically designed for glass, such as specialized glass epoxy or silicone adhesives.

By properly preparing the surface and choosing the right adhesive, you can achieve stronger, more durable bonds. Prioritize thorough cleaning and follow the recommended application steps to enhance the reliability and longevity of your glass repairs. Opt for the right tools and materials to ensure your glass items withstand environmental stressors and remain intact over time.

Frequently Asked Questions

Does JB Weld work on glass?

JB Weld can work on glass, but it is not ideal due to weak adhesion, leading to unreliable bonds. For better results, adhesives specifically formulated for glass are recommended.

Which JB Weld product is best for glass bonding?

None of the JB Weld products, including Standard JB Weld, J-B KwikWeld, J-B WaterWeld, or J-B ClearWeld, are specifically designed for glass bonding. Consider specialized glass adhesives for optimal results.

How should I prepare the glass surface before using JB Weld?

To prepare the glass surface, ensure thorough cleaning to remove contaminants using a razor blade and alcohol. Rinse and dry the surface, and lightly scuff the area with fine-grit sandpaper to enhance adhesion.

What is the curing time for JB Weld on glass?

JB Weld typically sets within 4-6 hours, with a full cure taking around 24 hours to reach maximum strength. Environmental factors like temperature and humidity can affect these times.

Is JB Weld a durable option for glass repairs?

JB Weld has limited adhesion on glass and poor durability over time, especially under environmental stressors. For robust and long-lasting repairs, consider using adhesives specifically designed for glass.

What alternative adhesives are recommended for glass repairs?

For strong, durable bonds on glass, specialized glass epoxy, silicone adhesives, and polyurethane adhesives are recommended over JB Weld.

Are there any tips for achieving optimal results with JB Weld on glass?

Achieve optimal results by thoroughly cleaning and preparing the glass surface, following package guidelines for mixing and application, and allowing adequate curing time. However, specialized glass adhesives are generally preferred for reliable repairs.