Does JB Weld Work on Brass? Tips for Effective Bonding

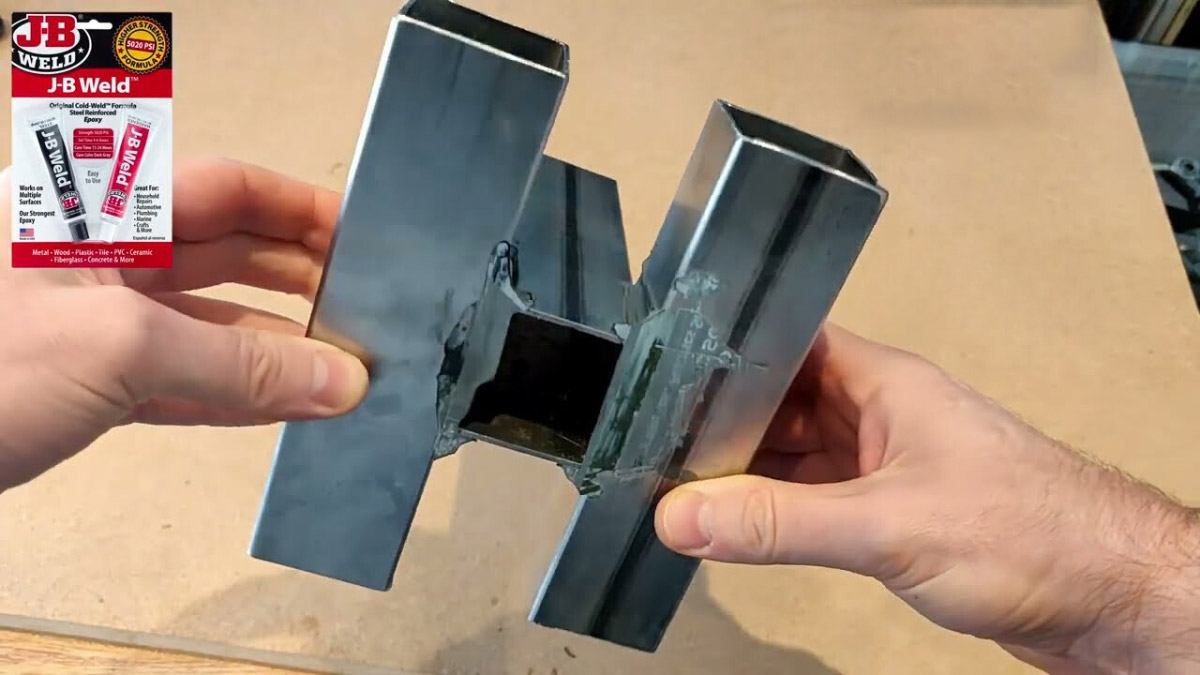

When it comes to repairing or bonding brass, you might wonder if JB Weld is up to the task. Known for its strength and versatility, JB Weld has become a go-to adhesive for many DIY enthusiasts and professionals. But does it really work on brass?

Brass, an alloy of copper and zinc, presents unique challenges due to its composition and applications. Whether you’re fixing a broken brass fitting or creating a custom piece, understanding how JB Weld interacts with this metal can save you time and effort. Let’s jump into the specifics and see if JB Weld is the right choice for your brass projects.

Key Takeaways

- JB Weld is effective in bonding brass, offering a strong adhesive solution for various brass applications when surfaces are properly prepared.

- Brass, an alloy of copper and zinc, has specific properties like corrosion resistance, high thermal and electrical conductivity, and malleability, making it widely used in various industries.

- Successful JB Weld applications require thorough surface cleaning and sanding, followed by precise mixing and application of the epoxy components.

- JB Weld provides strong adhesion with a tensile strength of 5020 PSI, and is durable, waterproof, petroleum, and chemical-resistant.

- Consider both advantages, like versatile compatibility and ease of use, and disadvantages, such as potential appearance mismatches and temperature sensitivity, when using JB Weld on brass.

Properties of Brass

Brass, an alloy of copper and zinc, exhibits unique characteristics that make it versatile and widely used in various applications. Understanding these properties helps when considering repair methods like JB Weld.

Characteristics of Brass

- Composition: Brass contains copper and zinc, with varying proportions to create different types. Higher zinc content increases strength and ductility.

- Corrosion Resistance: Brass resists corrosion, particularly from seawater and industrial atmospheres.

- Thermal Conductivity: Brass has high thermal conductivity, making it efficient in heat transfer applications.

- Malleability: Brass is highly malleable, ideal for shaping and forming without cracking.

- Electrical Conductivity: Brass offers good electrical conductivity, suitable for electrical components.

| Property | Description |

|---|---|

| Composition | Copper and zinc, variable proportions |

| Corrosion Resistance | Resistant to seawater and industrial atmospheres |

| Thermal Conductivity | High, efficient in heat transfer applications |

| Malleability | High, easy to shape without cracking |

| Electrical Conductivity | Good, used in electrical components |

- Musical Instruments: Brass’s acoustic properties make it ideal for trumpets, trombones, and other instruments.

- Plumbing and Heating: Corrosion resistance and thermal conductivity suit use in pipes, valves, and radiators.

- Machinery and Engines: Brass’s strength and machinability are beneficial in precision components.

- Electrical Equipment: Good conductivity and durability make it common in terminals and connectors.

- Decorative Items: Malleability and aesthetic appeal lead to frequent use in jewelry and household décor.

- Examples: Trumpets, pipes, engine parts, terminals, and jewelry.

Understanding brass’s properties and common applications informs your decision on using JB Weld for repairs.

Effectiveness of JB Weld on Brass

When considering JB Weld for brass repairs or bonding, its reputation for strength and versatility makes it a popular choice. JB Weld, an epoxy adhesive, is known for its ability to bond various metals, including brass, when used correctly. Below, key aspects of its effectiveness are detailed.

Adhesion and Bonding

To achieve a strong bond when using JB Weld on brass, surface preparation is crucial. Follow these steps:

- Clean the Surface: Remove any grease, oil, or debris.

- Scuff the Surface: Use sandpaper to create a rough texture, improving adhesion.

- Mix the Epoxy: Combine the components as per instructions.

The epoxy, once mixed and applied correctly, forms a strong bond with the brass.

Adhesion Strength

JB Weld boasts a tensile strength of 5020 PSI. This strength indicates its ability to handle various applications involving brass. But, the bond’s actual strength can vary depending on surface preparation quality and specific bonding conditions.

Durability and Longevity

Fully cured, JB Weld is:

- Waterproof: Making it suitable for both indoor and outdoor applications.

- Petroleum Resistant: Withstanding exposure to fuels and oils.

- Chemical Resistant: Remaining durable when exposed to various chemicals.

- Heat Resistant: Withstanding temperatures up to 550°F (287°C), suitable for high-temperature environments.

Summary

By following proper preparation steps, JB Weld can form a durable and strong bond with brass. Consideration of the specific application and environment ensures maximum effectiveness and longevity.

Application Process

Successful JB Weld application on brass hinges on proper surface preparation and step-by-step execution. Accurate steps ensure a robust bond and lasting durability.

Surface Preparation

- Cleaning the Brass Surfaces:

- Remove dirt, oil, or residue using a solvent like acetone or brake cleaner. Ensuring a clean surface prevents contaminants from weakening the bond.

- Sanding Mating Areas:

- Lightly sand the brass surfaces to enhance adhesion. This roughens the surface, providing more area for the epoxy to grip.

Step-by-Step Guide

- Mixing the Epoxy:

- JB Weld consists of two components: liquid steel/epoxy resin and hardener.

- Mix equal portions of resin and hardener until achieving a uniform color.

- Applying the Epoxy:

- Spread the mixed epoxy onto prepared brass surfaces.

- Align the surfaces correctly and provide support if necessary to maintain position.

Key Terms

- Epoxy Resin: A high-strength adhesive component.

- Hardener: A substance that facilitates the curing process of the epoxy resin.

- Uniform Color: Indicates proper mixing of epoxy resin and hardener.

Detailed Steps Overview

| Step | Action | Tools Needed | Duration |

|---|---|---|---|

| Cleaning Surfaces | Remove contaminants with solvent | Acetone/Brake Cleaner | 5-10 minutes |

| Sanding Areas | Lightly sand the brass surfaces for better adhesion | Sandpaper | 5-10 minutes |

| Mixing Epoxy | Combine equal parts of resin and hardener | Disposable Stick | 2-3 minutes |

| Applying Epoxy | Spread mixed epoxy onto surfaces and align properly | Applicator/Spreader | 5-10 minutes |

Action Point

Complete proper surface preparation and follow the detailed steps to ensure a strong, durable bond using JB Weld on brass.

Pros and Cons

When considering JB Weld for brass repairs, it’s important to weigh the advantages and disadvantages to ensure it’s the right choice for your project.

Advantages

Compatibility

JB Weld works effectively on brass, as it’s not listed among the materials it doesn’t adhere to, such as certain rubbers and plastics.

Strength

The adhesive provides a robust bond with a tensile strength of up to 4,000 PSI, making it suitable for demanding brass applications.

Chemical Resistance

After curing, JB Weld becomes resistant to water, petroleum, various chemicals, and acids, enabling its use in diverse environments.

Ease of Use

Application is straightforward; simply mix the epoxy’s two components in equal parts, enhancing user convenience.

Disadvantages

Appearance

JB Weld is black, which might not blend well aesthetically with brass, especially in visible areas.

Temperature Sensitivity

Although durable, JB Weld might not be suitable for high-temperature applications beyond its maximum tolerance.

By evaluating these pros and cons, you can determine if JB Weld is the right fit for your brass repair needs.

Conclusion

JB Weld proves to be a reliable adhesive for brass, offering strong bonding capabilities and resistance to various elements. By following proper surface preparation steps, you can achieve durable and effective repairs or custom projects. While there are some aesthetic and temperature limitations, the benefits often outweigh these drawbacks. With JB Weld, you can confidently tackle a range of brass applications, from plumbing to decorative items, knowing that your bond will hold strong.

Frequently Asked Questions

Can JB Weld bond brass effectively?

Yes, JB Weld can bond brass effectively when proper surface preparation is done. This includes cleaning, scuffing the surface, and correctly mixing the epoxy.

What is the tensile strength of JB Weld on brass?

JB Weld has a tensile strength of up to 5020 PSI, making it strong enough for a variety of applications involving brass.

What special steps are needed to prepare brass surfaces for JB Weld?

Clean the brass surfaces with a solvent, lightly sand them to improve adhesion, and mix the epoxy components thoroughly until a uniform color is achieved.

Is JB Weld waterproof once cured?

Yes, JB Weld is waterproof after it fully cures, making it suitable for both indoor and outdoor applications.

Can JB Weld resist high temperatures?

Yes, JB Weld is heat resistant up to 550°F (287°C), allowing for use in high-temperature applications within this range.

Are there any disadvantages to using JB Weld on brass?

The main disadvantages are the black color of JB Weld, which may not blend aesthetically with brass, and temperature sensitivity beyond its resistance range.

What are common applications of brass that JB Weld can be used for?

JB Weld can be used for repairing or bonding brass in musical instruments, plumbing and heating systems, machinery and engines, electrical equipment, and decorative items.

Why is surface preparation important when using JB Weld on brass?

Proper surface preparation ensures a strong bond by removing contaminants and improving adhesion through cleaning and scuffing.

Is JB Weld chemical resistant?

Yes, once fully cured, JB Weld is resistant to various chemicals, increasing its durability for different uses.

How long does it take for JB Weld to fully cure on brass?

JB Weld typically takes 15-24 hours to fully cure, ensuring a solid and durable bond for the repaired or bonded brass surfaces.