Bondo vs JB Weld: Choosing the Best Adhesive for Your Repair Needs

When it comes to DIY repairs, choosing the right adhesive can make all the difference. Bondo and JB Weld are two popular options, but how do you know which one suits your project best? Both have their strengths and weaknesses, and understanding these can save you time, money, and frustration.

Bondo is often the go-to for auto body repairs, thanks to its quick-drying properties and ease of sanding. On the other hand, JB Weld offers a strong, long-lasting bond that’s perfect for metal, wood, and even some plastics. By comparing their features, you’ll be better equipped to tackle your next repair job with confidence.

Key Takeaways

- Bondo vs. JB Weld: Bondo is a polyester-based filler better suited for cosmetic repairs, while JB Weld is an epoxy-based adhesive ideal for structural and demanding fixes.

- Ease of Use: Bondo is easier to apply and sand, making it convenient for quick, smooth finishes. In contrast, JB Weld requires mixing and is more challenging to sand, suited for projects needing high strength.

- Durability: JB Weld offers superior strength and durability, ideal for heavy-duty repairs and areas exposed to high stress or moisture. Bondo, however, may crack over time and isn’t suitable for high-stress applications.

- Drying Time: Bondo dries quickly within 10-15 minutes, beneficial for fast projects. JB Weld has a longer curing time of 4-6 hours, but results in a more robust and durable bond.

- Application Suitability: Use Bondo for auto bodywork and cosmetic fixes on various surfaces. JB Weld is best for structural repairs, particularly with metal, wood, and some plastics, ensuring long-lasting bonds.

Overview Of Bondo And JB Weld

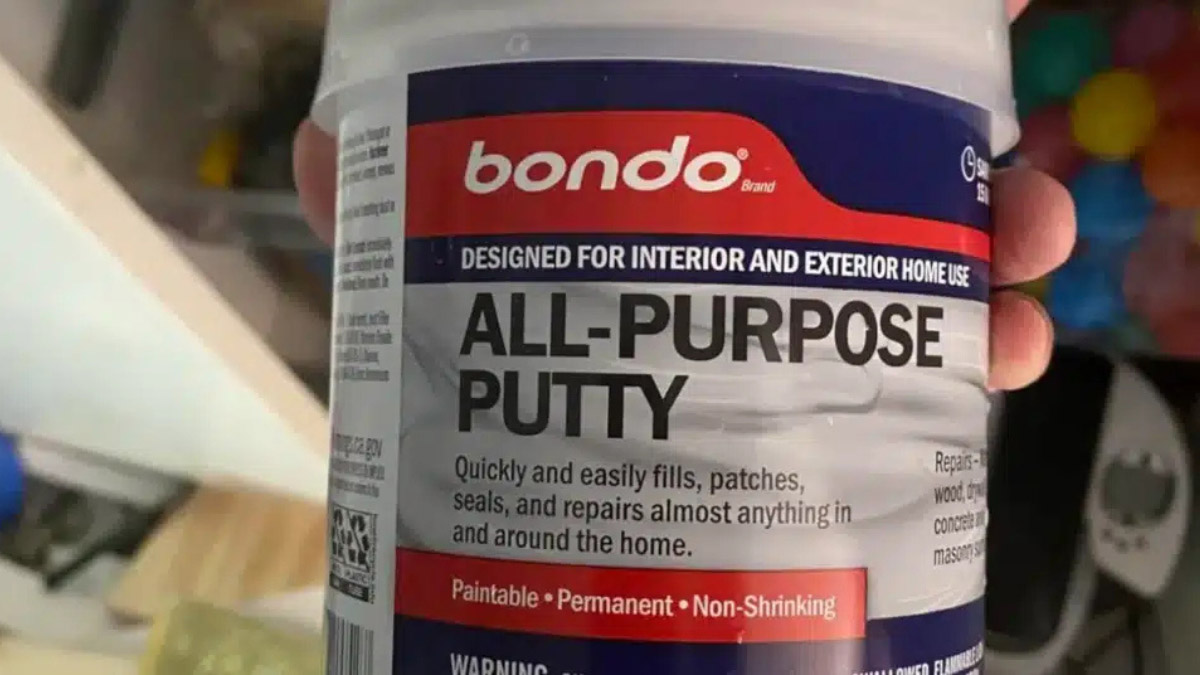

Bondo

- Type: Polyester filler

- Bondo is a polyester-based filler. It’s commonly used in automotive and woodworking applications.

- Ease of Application: Easy to apply and spread

- Users find Bondo straightforward to apply. You can easily spread it over surfaces needing repair.

- Sanding: Easy to sand

- Bondo’s softer texture makes it simple to sand, allowing for a smooth finish. This characteristic is particularly beneficial when prepping surfaces for painting.

- Hardness: Softer compared to epoxy

- Bondo is softer than JB Weld, making it less suitable for structural repairs but ideal for cosmetic fixes.

- Use Cases: Filling small imperfections and smoothing surfaces

- Bondo is effective for filling small dents, cracks, and other imperfections in various surfaces. It’s often used in auto body work and woodworking to create smooth finishes.

JB Weld

- Type: Epoxy-based adhesive

- JB Weld is an epoxy-based adhesive known for its strong bonding properties. It’s suitable for more demanding repair tasks.

- Ease of Application: More challenging to apply

- Applying JB Weld can be a bit trickier. You need to mix it thoroughly before application, which might require some practice.

- Sanding: Difficult to sand

- Due to its hardened epoxy nature, JB Weld is more difficult to sand. This makes it better suited for repairs where sanding isn’t required post-application.

- Hardness: Hard and durable

- JB Weld offers impressive hardness and durability. It’s perfect for structural repairs and applications demanding high strength.

- Use Cases: Repairing metal, filling holes, creating strong bonds

- JB Weld excels in repairing metal, filling sizable holes, and creating robust bonds. It’s machinable, so you can drill and tap into it after curing.

Comparison Table

| Feature | Bondo | JB Weld |

|---|---|---|

| Type | Polyester filler | Epoxy-based adhesive |

| Application | Easy to apply | More challenging to apply |

| Sanding | Easy | Difficult |

| Hardness | Softer | Hard and durable |

| Use Cases | Filling small imperfections, smoothing surfaces | Repairing metal, filling holes, creating strong bonds |

Summary

Selecting between Bondo and JB Weld depends on your project’s requirements. Use Bondo for easy application and smooth finishes. Opt for JB Weld for strong, durable bonds and demanding repairs. Understanding these key differences helps you choose the right product for your specific needs.

Key Features Compared

Strength And Durability

- Bondo: Bondo, a polyester-based filler, is generally softer and less durable than epoxy-based fillers. It suits cosmetic applications but lacks the strength required for structural repairs.

- JB Weld: JB Weld uses an epoxy-based solution, offering significantly higher strength and durability. It’s ideal for metal repairs and filling holes that need machining.

Ease Of Use

- Bondo: Bondo is relatively easy to apply and sand, perfect for smoothing surfaces. But, it doesn’t adhere as well to some materials compared to JB Weld.

- JB Weld: JB Weld requires mixing two components, making it more cumbersome to apply. It adheres better to various surfaces, including metal, though it’s harder to sand than Bondo.

Drying And Curing Time

- Bondo: Bondo dries quickly, often within 10-15 minutes, making it ideal for rapid projects.

- JB Weld: JB Weld takes longer to cure, typically around 4-6 hours for a full set, providing a more robust and durable bond after curing.

- Bondo: Bondo works well for cosmetic fixes on car bodies, wood, and other surfaces needing smooth finishes.

- JB Weld: JB Weld excels in more demanding applications involving metal, wood, and some plastics, providing a solid bond in a variety of conditions.

| Feature | Bondo | JB Weld |

|---|---|---|

| Type | Polyester-based | Epoxy-based |

| Strength | Moderate | High |

| Durability | Less durable | Highly durable |

| Ease Of Use | Easy to apply | Requires mixing |

| Adhesion | Moderate | Strong |

| Sanding | Easy | Difficult |

| Drying Time | 10-15 minutes | 4-6 hours |

| Versatility | Cosmetic fixes | Structural repairs |

Use this comparison to decide which adhesive best suits your project’s requirements. Bondo excels in cosmetic applications while JB Weld offers high strength and durability for more demanding repairs. Choose based on the specifics of what you’re repairing to achieve the best results.

Common Applications

Automotive Repairs

Both Bondo and JB Weld have distinct advantages in automotive repairs.

Bondo

- Dent Filling: Ideal for filling dents, scratches, and holes in auto bodywork due to its easy application and sanding properties.

- Surface Work: Works well on car surfaces but requires proper sealing to avoid water absorption and rust development.

- Polyester-Based: Bondo’s polyester composition makes it easy to shape and sand, perfect for getting a smooth finish.

JB Weld

- Rust Hole Repair: Suitable for repairing metal parts, including rust holes, with its strong bond to metal surfaces.

- Epoxy-Based: This epoxy product doesn’t absorb water, preventing rust, and is highly durable.

- Strength and Durability: Offers a robust and less prone to cracking solution but is harder to sand than Bondo.

Household Fixes

For household maintenance and repairs, both products offer various applications.

Bondo

- Wall Repairs: Effective for filling holes and cracks in walls, creating a smooth finish after sanding.

- Furniture Repair: Capable of mending broken or chipped furniture, allowing reshaping and easy sanding.

- General Purpose: Versatile for general-purpose filling tasks around the house.

JB Weld

- Metal Fixtures: Ideal for repairing metallic household items, ensuring a strong, lasting bond.

- Water-Exposed Areas: Suitable for areas prone to moisture due to its non-absorbent epoxy nature.

- Durability: Known for its robust adhesion, making it a long-term solution for structural fixes.

Craft And Hobby Projects

Both Bondo and JB Weld can enhance and repair your craft and hobby works.

Bondo

- Modeling: Useful for making smooth and detailed models and sculptures, thanks to its easy shaping capability.

- Customized Parts: Perfect for creating customized parts and elements that require finishing.

- Lightweight Projects: Adequate for projects that don’t require extreme durability.

- Metallic Crafts: Great for assembling and repairing metal sculptures and craft items due to its strong bond.

- Durable Creations: Suitable for crafting items that require high strength and durability which won’t be subject to frequent reshaping.

- Complex Assemblies: Work well for complex or detailed assemblies where a strong bond is crucial.

Comparison Table

| Feature | Bondo | JB Weld |

|---|---|---|

| Composition | Polyester-based | Epoxy-based |

| Best For | Cosmetic repairs, auto body | Structural repairs, metalwork |

| Water Absorption | Yes, if not sealed | No |

| Ease of Sanding | Easy | Difficult |

| Dry/Cure Time | 10-15 minutes | 4-6 hours |

| Durability | Less durable | Highly durable, robust |

Advantages And Disadvantages

Choosing between Bondo and JB Weld for your repair projects can significantly impact the project’s success. Understanding the advantages and disadvantages of each adhesive will help you make an well-informed choice.

Pros Of Bondo

- Ease of Use: Bondo is designed for easy application and sanding. This makes it perfect for smoothing surfaces and filling small imperfections in metal.

- Surface Finish: It provides a smooth finish that’s easy to paint over, crucial for automotive bodywork.

- Cost-Effective: Bondo is generally less expensive than JB Weld, making it ideal for large area applications.

- Versatility: You can use Bondo on various surfaces, including metal, wood, and fiberglass, making it suitable for both small and large repairs.

Cons Of Bondo

- Strength: Bondo lacks the strength of JB Weld, making it unsuitable for structural repairs or high-stress areas.

- Durability: It can crack over time, especially if the surface isn’t properly prepared.

- Heat Resistance: Bondo doesn’t perform well in high-temperature conditions, limiting its use in areas exposed to heat.

Pros Of JB Weld

- High Strength: JB Weld creates a strong durable bond, making it ideal for heavy-duty repairs.

- Multipurpose: It works on various materials, including metal, wood, and some plastics, making it versatile for multiple applications.

- Heat and Chemical Resistance: JB Weld withstands high temperatures and various chemicals, enhancing its durability.

- Structural Repairs: Due to its strength, JB Weld is suitable for structural and load-bearing repairs.

- Complex Application: Applying JB Weld is more challenging since it requires mixing two components, making it less convenient.

- Longer Curing Time: It typically takes 4-6 hours to cure, compared to Bondo’s quicker drying time of 10-15 minutes.

- Cost: JB Weld is generally more expensive, which can be a consideration for large projects.

| Feature | Bondo | JB Weld |

|---|---|---|

| Ease of Use | Easy to apply and sand | Requires mixing components |

| Surface Finish | Smooth, paintable | Rough finish, harder to sand |

| Cost | Less expensive | More expensive |

| Versatility | Metal, wood, fiberglass | Metal, wood, some plastics |

| Strength | Lower | Higher |

| Heat Resistance | Low | High |

| Durability | Prone to cracking | Highly durable |

| Ideal Applications | Cosmetic fixes, auto bodywork | Structural repairs, metal fixtures |

User Reviews And Feedback

Durability And Strength

Users often highlight the durability and strength of JB Weld and Bondo, reflecting on their performance in various applications.

JB Weld:

- Strength: Many users consider JB Weld to deliver superior strength. It’s an epoxy-based product that hardens to a metal-like consistency, making it excellent for structural repairs.

- Durability: Reviews frequently praise JB Weld for its mechanical stress resistance and water resistance. Users report it holding up well under various conditions.

Bondo:

- Flexibility: Users acknowledge Bondo as easier to work with due to its softer consistency. But, it doesn’t match JB Weld in durability.

- Cosmetic Applications: Many reviews note Bondo’s suitability for cosmetic repairs where a smooth finish is essential. But, it may not endure stress or moisture well.

Ease Of Application And Sanding

Application ease and the sanding process are pivotal in user experiences with both JB Weld and Bondo.

Bondo:

- Application: Users appreciate Bondo’s easy application. Its smoother consistency allows for straightforward spreading and shaping.

- Sanding: Many remark on the ease of sanding Bondo due to its softer nature, making it ideal for tasks requiring fine surface preparation.

JB Weld:

- Application: Reviews often mention the added challenge of applying JB Weld. It requires mixing two components, which some find cumbersome.

- Sanding: Users commonly find JB Weld more difficult to sand. Its hard, epoxy-like finish demands more effort during surface preparation.

Comparative User Ratings

| Attribute | JB Weld Rating | Bondo Rating |

|---|---|---|

| Strength and Durability | 4.8/5 | 3.6/5 |

| Ease of Application | 3.9/5 | 4.5/5 |

| Sanding Difficulty | 2.8/5 | 4.6/5 |

| Cosmetic Finish | 3.7/5 | 4.7/5 |

| Water Resistance | 4.9/5 | 3.4/5 |

User Feedback Summary

- Structural Repairs: Users prefer JB Weld for heavy-duty tasks due to its high strength and durability.

- Cosmetic Repairs: Bondo is popular for minor repairs and finishing tasks because of its ease of use and smooth finish.

- Projects Exposed to Moisture: JB Weld is the go-to, given its excellent resistance to water.

- Structural Needs: Choose JB Weld if your project requires strong, lasting repairs.

- Cosmetic Finishing: Opt for Bondo for tasks needing a smooth, easy-to-prepare surface.

- Moisture Exposure: Select JB Weld for repairs in areas subject to water or high humidity.

Conclusion

Choosing between Bondo and JB Weld depends on the specific needs of your project. If you’re looking for an easy-to-apply solution for cosmetic repairs or smoothing surfaces, Bondo’s quick-drying and easy sanding properties make it a great choice. On the other hand, if your project requires a strong, durable bond, especially for metal or areas exposed to moisture, JB Weld’s high strength and resistance to heat and chemicals make it the better option.

By understanding the strengths and weaknesses of each adhesive, you can confidently select the right one for your repair needs, ensuring successful and long-lasting results.

Frequently Asked Questions

What is the primary use of Bondo?

Bondo is primarily used for auto body repairs. It is a polyester filler that is easy to apply and sand, making it ideal for filling small imperfections, dents, and scratches to achieve smooth finishes.

What materials is JB Weld effective on?

JB Weld is effective on various materials, including metal, wood, and some plastics. It is known for providing a strong and durable bond, making it suitable for structural repairs.

How long does Bondo take to dry?

Bondo dries relatively quickly, typically within 10-15 minutes. This quick drying time allows for fast application and sanding.

Is JB Weld heat resistant?

Yes, JB Weld is heat resistant. It can withstand high temperatures, making it suitable for applications exposed to heat and chemicals.

Can Bondo be used for structural repairs?

Bondo is generally not recommended for structural repairs due to its lower strength and durability. It is best used for cosmetic repairs, such as smoothing surfaces and filling small imperfections.

How long does JB Weld take to cure?

JB Weld typically takes around 4-6 hours to cure. The longer curing time results in a more robust bond, suitable for applications requiring high strength.

Is Bondo easy to sand?

Yes, Bondo is easy to sand. Its quick-drying and easy-sanding qualities make it popular for achieving smooth finishes in auto body repairs and other cosmetic applications.

What are the main advantages of JB Weld over Bondo?

The main advantages of JB Weld over Bondo include its higher strength, durability, and heat resistance. JB Weld is ideal for structural repairs and applications requiring a strong, long-lasting bond.

Can JB Weld be used for automotive repairs?

Yes, JB Weld can be used for various automotive repairs. It is particularly effective for repairing rust holes and metal fixtures in vehicles.

What is the cost-effectiveness of Bondo compared to JB Weld?

Bondo is generally more cost-effective compared to JB Weld. It is affordable and versatile for cosmetic repairs, while JB Weld, albeit more expensive, offers superior strength and durability for structural applications.