Glue for Plastic: Top Choices for Strong, Reliable Bonds

Ever tried fixing a broken plastic item only to find it falling apart again? Finding the right glue for plastic can feel like a challenging job with so many options out there. Whether you’re repairing a favorite toy, mending household items, or tackling a DIY project, the right adhesive makes all the difference.

Understanding the types of plastic and the adhesives that work best with each can save you time and frustration. Some glues form strong bonds with certain plastics but fail miserably with others. In this guide, you’ll discover the best glues for various plastic types, ensuring your repairs are durable and long-lasting.

Key Takeaways

- Identify Plastic Type: Knowing the specific type of plastic (e.g., PE, PP, PS) is essential for selecting the appropriate adhesive, as different plastics respond differently to various adhesives.

- Adhesive Selection: Super glue, plastic bonder, epoxy, and hot melt adhesives each have unique properties and are suitable for different types of plastics and repair needs.

- Surface Preparation: Properly cleaning and roughening the surfaces before applying glue increases the chances of a strong bond.

- Application Tips: Following manufacturer instructions for mixing and clamping ensures better adhesion and durability.

- Environmental Considerations: Consider factors like exposure to water, UV light, and temperature variations when choosing an adhesive to ensure long-lasting repairs.

- Safety Measures: Always use gloves, work in well-ventilated areas, and follow safety guidelines to prevent accidents and ensure effective use of adhesives.

Understanding Plastic Glue

Gluing plastic involves selecting the right adhesive based on the specific type of plastic and project needs. Factors like the plastic’s composition and the adhesive’s properties greatly influence the bonding strength and durability.

Types of Adhesives for Plastic

Super Glue (Cyanoacrylate)

- Characteristics: Dries quickly, often within seconds. Suitable for small repairs and precise applications.

- Usage: Works well on numerous plastics, excluding polyethylene (PE) and polypropylene (PP). Popular products include Loctite Super Glue Gel Control and LePage Super Glue Gel Control.

- Limitations: May not adhere effectively to certain plastics. Fast-drying nature can make handling tricky.

Plastic Bonder

- Characteristics: Specialized adhesives designed for plastic. Commonly available in two-part systems needing mixing.

- Usage: Ideal for harder plastics like polystyrene (PS) and high-density plastics.

Important Considerations

To ensure your projects are successful, pay attention to the following factors:

- Plastic Type: Know the specific plastic type (e.g., PE, PP, PS) to choose a compatible adhesive. For instance, super glue isn’t effective on PE and PP.

- Adhesive Properties: Understand drying time, bonding strength, and application method. Quick-drying adhesives like cyanoacrylate suit small repairs, while plastic bonders are better for larger or more complex tasks.

- Environmental Conditions: Consider exposure to elements like water, UV light, and temperature variations. Some adhesives provide better resistance to certain environmental factors.

Application Tips

- Surface Preparation: Clean the plastic surfaces thoroughly to remove any dust, oil, or contaminants.

- Mixing: Follow the manufacturer’s instructions for two-part adhesives to ensure proper bonding.

- Clamping: Hold the parts together until the adhesive sets to maintain alignment and bonding strength.

| Adhesive Type | Drying Time | Suitable Plastics | Popular Products | Limitations |

|---|---|---|---|---|

| Super Glue | Seconds | Various (excl. PE, PP) | Loctite Super Glue Gel, LePage Super Glue | Difficult to handle due to quick drying |

| Plastic Bonder | Varies | Harder plastics (PS, high-density) | Various brands | Requires mixing |

Choosing the right plastic glue ensures strong, lasting repairs. Matching the adhesive to the plastic type and considering environmental conditions can significantly impact the success of your project.

Types of Plastic Glue

Choosing the right adhesive is crucial for effective plastic repairs. Various types of plastic glue cater to diverse plastic materials and application requirements.

Super Glue (Cyanoacrylate)

Characteristics

- Quick-drying: Bonds almost instantly.

- Strong bond: Effective for small repairs.

- Versatile: Works on different plastics.

Suitable Plastics

- ABS

- PVC

- Polycarbonate

- Other similar plastics

Limitations

- Ineffective on smooth or oily surfaces.

- Requires primer for polypropylene and polyethylene.

Epoxy Adhesive

Characteristics

- Strong bond: Highly effective for durable repairs.

- Versatile: Suitable for various applications.

- Two-part system: Requires mixing resin and hardener.

Suitable Plastics

- ABS

- Polycarbonate

- Fiberglass

Limitations

- May require surface preparation.

- Longer curing time compared to super glue.

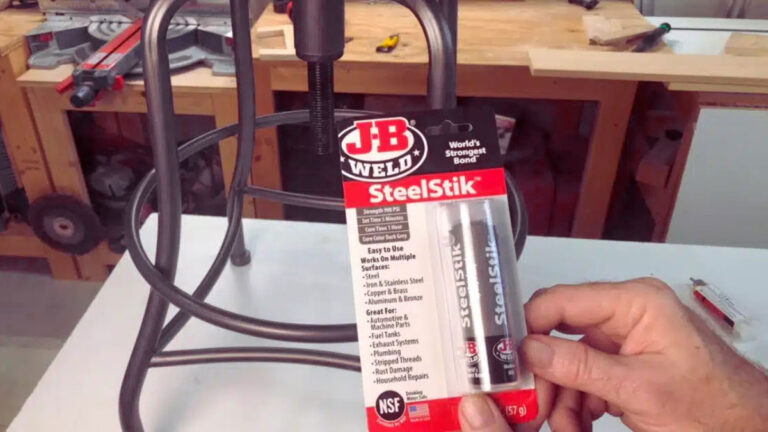

Plastic Bonder

Characteristics

- High-strength bond: Exceptional for harder plastics.

- Two-part adhesive: Mixing required for activation.

- Heat-resistant: Suitable for thermal applications.

Suitable Plastics

- Polypropylene

- Polyethylene

- TPO

Limitations

- Requires accurate mixing.

- Longer preparation and curing time.

Hot Melt Adhesive

Characteristics

- Quick setting: Bonds within minutes.

- Thermoplastic: Melts upon heating and solidifies when cooled.

- Flexible: Suitable for various non-structural applications.

Suitable Plastics

- Polyethylene

- Polypropylene

- PVC

Limitations

- Limited strength: Not ideal for high-stress applications.

- Requires hot glue gun.

| Adhesive Type | Bonding Strength | Suitable Plastics | Curing Time | Limitations |

|---|---|---|---|---|

| Super Glue (Cyanoacrylate) | Moderate | ABS, PVC, Polycarbonate, Others | Instant | Not effective on smooth surfaces, needs primer for PP and PE |

| Epoxy Adhesive | High | ABS, Polycarbonate, Fiberglass | Hours | Requires surface prep, longer cure time |

| Plastic Bonder | Very High | Polypropylene, Polyethylene, TPO | Hours | Needs precise mixing, longer preparation and cure time |

| Hot Melt Adhesive | Moderate | Polyethylene, Polypropylene, PVC | Minutes | Limited strength, needs hot glue gun |

Understanding the specific needs of your plastic repair project ensures you select the most effective adhesive. This knowledge helps you achieve durable and lasting repairs.

How to Choose the Right Glue for Plastic

Selecting the correct glue for your plastic repair projects can ensure strong, lasting bonds. Evaluating the type of plastic and the adhesive’s compatibility is crucial.

Identifying Plastic Type

Plastics are classified by recycling symbols with numbers from 1 to 7. Identifying these types helps in selecting the right adhesive. Here are some common plastics and suitable glues:

- High Density Polyethylene (HDPE) (Recycling Symbol 1)

- Best Glue: Epoxy works best. Roughening the surface improves adhesion.

- High Density Polyethylene (HDPE) (Recycling Symbol 2)

- Best Glue: Plastic cement, cyanoacrylates, or epoxies. Surface roughening is critical.

- Polyvinyl Chloride (PVC) (Recycling Symbol 3)

- Best Glue: Plastic cement, cyanoacrylates, or epoxies.

- Low Density Polyethylene (LDPE) (Recycling Symbol 4)

- Adhesion Issue: Not recommended for gluing due to low surface energy.

| Plastic Type | Recycling Symbol | Suitable Glues |

|---|---|---|

| HDPE | 1, 2 | Epoxy, Plastic Cement, Cyanoacrylates, Roughening |

| PVC | 3 | Plastic Cement, Cyanoacrylates, Epoxies |

| LDPE | 4 | Not recommended due to low surface energy |

Compatibility and Strength

Assessing an adhesive’s compatibility and strength with the plastic type is essential to ensure effective bonding.

-

Super Glue (Cyanoacrylate)

- Use: Quick fixes, small repairs

- Limitations: Ineffective on certain plastics like polyethylene and polypropylene

-

Epoxy

- Use: High-strength, durable repairs

- Process: Requires mixing and longer curing time

-

Plastic Cement

- Use: Common for model kits and PVC

- Strength: Provides a strong, plastic-weld-type bond

- Use: Quick-setting, low-strength repairs

- Limitations: Not suitable for high-stress applications

| Adhesive | Use | Limitations |

|---|---|---|

| Super Glue | Quick fixes, small repairs | Not effective on PE and PP |

| Epoxy | High-strength repairs | Requires mixing, long curing |

| Plastic Cement | Model kits, PVC | Strong bond |

| Hot Melt Adhesives | Quick-setting repairs | Low strength, not for high-stress areas |

Understanding these factors ensures strong and lasting plastic repairs. Always match the adhesive to the plastic type for optimal results.

Step-by-Step Guide to Gluing Plastic

Gluing plastic can be tricky, but with the right preparation and techniques, you can achieve durable and reliable bonds. Below is a detailed, step-by-step guide to ensure your plastic repairs are successful.

Surface Preparation

- Clean the Surface: Remove dirt, dust, oils, and other residues from the plastic surfaces. Use soap, specialized plastic cleaner, or isopropyl alcohol for cleaning. Thoroughly dry the surfaces post-cleaning to prevent moisture from affecting adhesion.

- Roughen the Surface: Sand the plastic surfaces lightly with 120 to 200 grit sandpaper to enhance adhesion. This step is essential, particularly for smooth or glossy plastics.

- Avoid Touching: Prevent contact with the cleaned plastic surfaces using your bare hands to avoid leaving oils that can weaken the bond.

Application Techniques

- Choose the Right Adhesive: Select an adhesive appropriate for the plastic you’re working with:

- Super Glue (Cyanoacrylate): This is effective for most plastics except polyethylene (PE) and polypropylene (PP).

- Epoxy: Suitable for high-strength repairs and works well on high-density polyethylene (HDPE) and other hard plastics.

- Plastic Cement: Best for models and PVC plastics due to its solvent-based bonding properties.

- Hot Melt Adhesives: Quick-setting but generally provide lower strength. Ideal for temporary or low-stress repairs.

Assembling Pieces

- Apply Adhesive: Spread a thin, even layer of adhesive on the prepared plastic surfaces. Ensure comprehensive coverage to avoid weak spots.

- Align Pieces: Carefully align the plastic pieces you need to bond—any misalignment can weaken the joint.

- Clamp the Pieces: Use clamps or heavy objects to hold the plastic pieces together. This ensures a tight bond and prevents movement during curing.

- Curing Time: Adhere to the adhesive manufacturer’s recommended curing time for optimal bond strength:

- Super Glue: Typically sets within a few minutes; full cure within 24 hours.

- Epoxy: Sets in 5-30 minutes; full cure in 24-72 hours.

- Plastic Cement: Bonds in seconds; fully cures within 24 hours.

- Hot Melt Adhesives: Sets within seconds; full strength reached immediately upon cooling.

Clean-Up and Finishing

- Remove Excess Adhesive: Wipe away any excess adhesive immediately to avoid hardened residue. Use a damp cloth for adhesives like Super Glue and epoxy.

- Sanding and Smoothing: If needed, lightly sand any rough or protruding adhesive spots once fully cured. This ensures a smooth finish.

- Final Cleaning: Clean the bonded plastic pieces with a mild detergent or isopropyl alcohol to remove any remaining surface dust or residue.

| Adhesive Type | Plastics Suitable For | Curing Time | Strength |

|---|---|---|---|

| Super Glue | Most except PE, PP | Sets in minutes; full cure in 24 hours | Medium to High |

| Epoxy | HDPE, hard plastics | Sets in 5-30 minutes; full cure in 24-72 hours | High |

| Plastic Cement | Models, PVC | Bonds in seconds; full cure in 24 hours | High |

| Hot Melt Adhesives | Temporary/low-stress repairs | Sets in seconds; full strength immediately | Low |

Taking these steps and using the right adhesive can significantly improve the durability and effectiveness of your plastic repairs.

Tips and Best Practices

Choosing the right glue for plastic repairs is crucial, but understanding how to use it effectively is equally important. Follow these tips to ensure strong, durable bonds and safe handling of adhesives.

Handling and Safety Precautions

Proper handling and safety precautions help avoid accidents and ensure effective use of adhesives.

Safety Gloves: Wear gloves to protect your skin from adhesives that could cause irritation or allergic reactions.

Ventilation: Use adhesives in a well-ventilated area to minimize inhalation of fumes, which can be harmful.

Protective Eyewear: Use safety glasses to prevent adhesive splashes from reaching your eyes.

Storage: Store glues in a cool, dry place, away from children and pets to prevent accidental exposure.

Spill Management: Keep a solvent like acetone on hand to clean up accidental spills quickly and safely.

Achieving Strong Bonds

Strong bonds depend on proper preparation and application techniques.

- Surface Preparation: Clean the surfaces to remove dirt, oil, or grease. Use isopropyl alcohol for effective cleaning.

- Roughening: Lightly sand the surfaces to create a better adhesion profile.

- Application: Apply a thin, even layer of adhesive on one surface. Avoid over-application as excess glue can weaken the bond.

- Alignment: Join the pieces immediately, ensuring proper alignment before the adhesive sets.

- Clamping: Use clamps to hold the pieces together during curing. Refer to the adhesive’s instructions for clamping duration and curing times.

Common Mistakes to Avoid

Avoid these common mistakes to enhance the effectiveness of your plastic repairs.

- Incorrect Adhesive Selection: Always match the type of glue to the plastic being bonded. For instance, Cyanoacrylate works well with most plastics but not with polyethylene or polypropylene.

- Dirty Surfaces: Neglecting proper cleaning can prevent adhesives from bonding effectively.

- Over-application: Using too much adhesive can lead to weak bonds and longer curing times.

- Misalignment: Failing to align parts correctly before the adhesive sets can compromise the bond’s strength and appearance.

- Ignoring Curing Times: Not allowing sufficient curing time can weaken the bond. Follow the adhesive’s guidelines for optimal results.

By following these tips and best practices, you can achieve stronger, more reliable plastic repairs while maintaining safety. Each step, from handling to application, plays a vital role in the success of your project.

Conclusion

Choosing the right glue for plastic repairs can make all the difference in achieving a strong and lasting bond. By understanding the type of plastic you’re working with and selecting the appropriate adhesive, you can tackle repairs with confidence and precision. Remember to prepare surfaces properly, follow application guidelines, and observe safety precautions to ensure effective results. With the right knowledge and tools, your plastic repairs will be more reliable and durable, saving you time and frustration in the long run.

Frequently Asked Questions

How can I repair broken plastic items effectively?

Choose the right adhesive based on the type of plastic and project requirements. Surface preparation and proper application techniques are crucial for a strong, durable bond.

Which adhesive is best for small plastic repairs?

Super Glue (Cyanoacrylate) is suitable for small repairs because it dries quickly, but it may not work well with certain plastics such as polyethylene (PE) and polypropylene (PP).

What adhesive should I use for harder plastics?

Plastic bonders are designed for harder plastics and provide strong, long-lasting bonds.

How can I identify the type of plastic I need to repair?

Check the recycling symbols (1 to 7) on the plastic item, which help identify the type and suggest compatible adhesives.

What is the recommended adhesive for High-Density Polyethylene (HDPE)?

Epoxy is recommended for HDPE due to its high-strength bonding properties.

Why is Low-Density Polyethylene (LDPE) not recommended for gluing?

LDPE has low surface energy, making it difficult for adhesives to create a strong bond.

Can hot melt adhesives be used on plastic repairs?

Hot melt adhesives set quickly but generally provide lower strength compared to other adhesive types.

What should I consider before starting a plastic repair project?

Understand the type of plastic, the adhesive properties, and the environmental conditions where the repair will be used.

How can I ensure a strong bond when gluing plastic?

Prepare the surface thoroughly, choose the right adhesive, apply it evenly, align the pieces accurately, and clamp them during the curing process.

What safety precautions should I take when using adhesives?

Wear gloves, ensure good ventilation, and use protective eyewear to ensure safe handling of adhesives.