Does JB Weld Work on Copper: Effective Repairs and Tips

Ever found yourself with a copper pipe or fitting that needs repair and wondered if JB Weld could be your go-to solution? You’re not alone. Many DIY enthusiasts and professionals alike turn to JB Weld for its reputation as a strong adhesive, but does it really work on copper?

Understanding the compatibility of JB Weld with copper can save you time, money, and a lot of frustration. Whether you’re fixing a leaky pipe or restoring an antique, knowing the ins and outs of this adhesive can make all the difference. Let’s jump into what makes JB Weld a potential game-changer for your copper repair needs.

Key Takeaways

- Effective Bonding: JB Weld can effectively bond copper to various materials, such as plastics and metals, making it versatile for a range of DIY projects and repairs.

- Limitations in Plumbing: JB Weld is not ideal for high-pressure plumbing repairs on copper pipes. Traditional methods like soldering or brazing are recommended for their durability and pressure resistance.

- Surface Preparation: For optimal results, ensure that copper surfaces are clean, dry, and roughed up with sandpaper or a wire brush to enhance adhesion.

- Proper Mixing and Curing: Mix the JB Weld components according to the instructions and allow adequate curing time (4-6 hours for initial set, up to 24 hours for full cure) for a strong bond.

- Alternative Methods: For applications requiring higher pressure and temperature resistance, consider alternative methods such as soldering or brazing, which offer more robust and durable bonds.

- Advantages and Disadvantages: JB Weld provides high temperature and chemical resistance but is not suitable for applications needing flexibility or withstanding high mechanical stress.

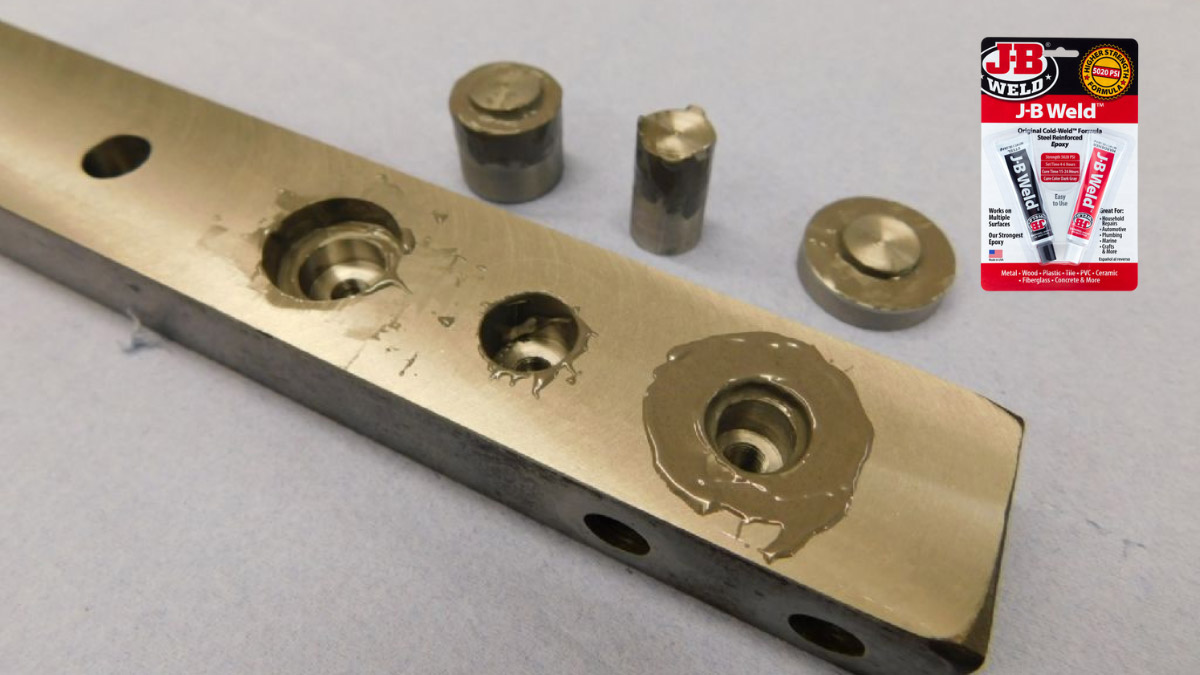

Applicability On Copper

JB Weld, known for its steel-reinforced epoxy, can bond copper effectively depending on the conditions and the specific use case. Understanding its strengths and limitations helps you make an well-informed choice for your copper repair needs.

Types Of Copper Repairs

- Bonding Copper To Other Materials:

When you need to join copper to materials like plastic, JB Weld proves effective. Numerous cases show it holding strong over several months. Its versatile nature makes it a good choice for mixed-material projects. - Repairing Copper Fixtures:

For minor fixes on copper fixtures like handles, knobs, or decorative elements, JB Weld offers a reliable solution. It forms a strong bond that can withstand normal use and wear. - Plumbing Repairs:

While JB Weld works for some copper repairs, you should be cautious with plumbing applications. It’s not ideal for sealing leaks in copper lines, especially those under pressure. The adhesive might not withstand the stress, leading to potential failure. Soldering or brazing is recommended for high-pressure scenarios due to their durability and resistance to water pressure.

Tips For Best Results

- Surface Preparation:

Ensure surfaces are clean and free of contaminants. Use sandpaper or a wire brush to roughen the surfaces to enhance adhesion. - Correct Mixing:

Mix the JB Weld components in the correct ratio as per the instructions. An improper mixture can affect the curing process and the bond strength. - Application:

Apply the mixed epoxy evenly to avoid weak spots. Use a spatula or similar tool to spread it uniformly over the surface. - Curing Time:

Allow adequate curing time, typically 4-6 hours for initial setting and up to 24 hours for full strength. Do not disturb the bonded area during this period. - Environmental Conditions:

Apply JB Weld in a controlled environment. Extreme temperatures or humidity levels can impact its effectiveness.

| Attribute | Details |

|---|---|

| Tensile Strength | 3980 psi |

| Temperature Resistance | Up to 550°F (287°C) |

| Curing Time | 4-6 hours (initial), 24 hours |

| Application Temperature | 50°F to 90°F (10°C to 32°C) |

| Bonding Materials | Metals, plastics, ceramics, woods |

Utilizing JB Weld for copper repairs requires a clear understanding of its properties and application methods. Proper preparation and following recommended steps ensure a strong, durable bond.

Step-by-Step Guide To Using J-B Weld On Copper

Using J-B Weld on copper requires careful attention to detail to ensure a strong, durable bond. Follow these steps to achieve optimal results.

Preparation and Cleaning

Proper preparation and cleaning are crucial for the epoxy to adhere effectively.

- Identify the Leak: Locate the exact spot of the leak on the copper pipe.

- Shut Off Water Supply: Ensure the water supply to the pipe is turned off to prevent further leakage.

- Clean the Area: Use a wire brush or sandpaper to thoroughly clean the area around the leak. Remove all corrosion and debris.

- Use a Cleaning Agent: Apply a cleaning agent, like brake cleaner, to remove any residue. Ensure the surface is dry before applying the epoxy.

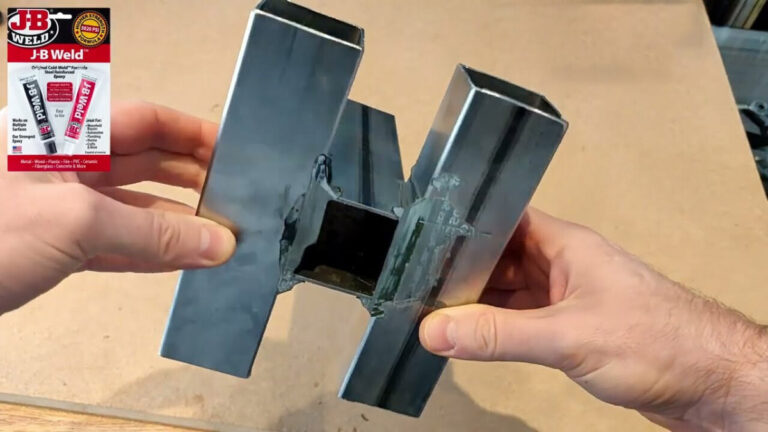

Application Process

Follow these steps to apply J-B Weld to the prepared copper surface.

- Mix the Epoxy: Follow the instructions on the J-B Weld packaging. Mix the two-part epoxy until it’s well combined.

- Apply the Epoxy: Spread the mixed epoxy over the cleaned area, covering the entire leak and any surrounding areas needing reinforcement. If necessary, you can form a metal patch to fit over the leak area with overlap.

Curing Time and Final Steps

Proper curing is essential for the epoxy to achieve its full strength.

- Allow Curing Time: Let the epoxy cure for the recommended time indicated on the J-B Weld packaging. This typically takes 4-6 hours for setting and 15-24 hours for a full cure.

- Inspect the Bond: Once fully cured, inspect the bond for any gaps or weak points. If needed, apply additional epoxy for reinforcement.

- Restore Water Supply: After ensuring the bond is strong and the area is completely dry, restore the water supply to test the repair.

| Step | Description |

|---|---|

| Identify the Leak | Locate the leak on the copper pipe. |

| Shut Off Water Supply | Turn off the water supply to prevent further leakage. |

| Clean the Area | Use a wire brush or sandpaper to remove corrosion and debris. |

| Use a Cleaning Agent | Apply a cleaner like brake cleaner to remove residue. Ensure the surface is dry. |

| Mix the Epoxy | Follow J-B Weld instructions to mix the two-part epoxy. |

| Apply the Epoxy | Cover the cleaned area with mixed epoxy. Consider a metal patch for larger leaks. |

| Allow Curing Time | Let the epoxy cure for 4-6 hours for setting, 15-24 hours for a full cure. |

| Inspect the Bond | Check for any gaps or weak points. Apply additional epoxy if needed. |

| Restore Water Supply | Once the bond is strong and dry, restore the water supply to check the repair. |

This guide ensures a secure and effective repair using J-B Weld on copper, combining detailed steps and essential information for optimal results.

Alternative Products And Methods

When dealing with copper, JB Weld might not be your best option. Understanding other products and methods can ensure a reliable, long-lasting bond.

Other Epoxies

JB Weld isn’t always optimal for copper, especially under high temperatures or chemical exposure.

- Limitations:

Certain epoxies offer specific advantages, but bonding copper demands more. - Typical epoxies might not withstand copper’s unique properties.

- Most epoxies lack the necessary thermal and chemical resistance.

Soldering And Brazing

Reliable alternatives like soldering and brazing provide robust bonds for copper.

- Soldering:

- Preparation: Clean and roughen surfaces of copper and other metals.

- Materials: Use silver solder and appropriate flux for best results.

- Procedure:

- Heat the metals.

- Apply solder at the joint.

- Allow it to cool and solidify.

- Brazing:

- Temperature: Requires higher temperatures than soldering.

- Strength: Forms stronger joints and works well with copper.

- Steps to Braze Copper:

- Clean the surfaces.

- Heat the metals using a torch.

- Apply the filler metal.

- Let it cool naturally.

| Method | Temperature | Materials Needed | Application Notes |

|---|---|---|---|

| Soldering | 400°F-700°F | Silver solder, flux | Best for fitting repairs, requires clean surfaces |

| Brazing | 1100°F-1500°F | Brazing rods, flux | Suitable for stronger joints, can handle higher pressures and temperatures |

Choosing the right method depends on the application’s requirements for heat and pressure resistance.

Pros And Cons Of Using J-B Weld On Copper

Pros

- Temperature Resistance

J-B Weld can handle temperatures up to 500°F. This makes it suitable for applications involving high heat, such as engine repairs or exhaust systems. - Chemical Resistance

Once cured, J-B Weld becomes chemically inert. This allows it to resist various chemicals commonly found in mechanical and automotive settings, ensuring a durable bond. - Adhesion

J-B Weld adheres well to metal surfaces, including copper. This creates a strong, reliable seal suitable for many repair tasks involving copper pipes, fittings, and surfaces.

Cons

- Not Suitable for High-Pressure Applications

While J-B Weld effectively bonds copper, it may not withstand high-pressure conditions. For applications requiring significant mechanical stress, alternative methods like brazing or soldering are recommended. - Limited Flexibility

J-B Weld lacks flexibility once cured. This inflexibility can be a disadvantage in scenarios requiring some degree of movement or elasticity in the bonded materials.

Summary

Using J-B Weld on copper offers advantages like high temperature and chemical resistance, and strong adhesion to metal surfaces. But, it may fall short in high-pressure applications and lacks post-cure flexibility, limiting its use cases to specific situations.

Conclusion

JB Weld offers a viable solution for many copper repair needs, especially when dealing with non-pressurized applications. Its strong adhesive properties and resistance to high temperatures and chemicals make it a popular choice among DIY enthusiasts and professionals alike. But, it’s crucial to understand its limitations, particularly for plumbing repairs under pressure, where soldering or brazing might be more appropriate.

Proper preparation and application are key to achieving a successful bond with JB Weld. By following the recommended steps and allowing adequate curing time, you can ensure a reliable repair. Always consider the specific requirements of your project to choose the most effective method, whether it’s JB Weld or an alternative like soldering or brazing, to achieve a durable and lasting repair on copper surfaces.

Frequently Asked Questions

Can JB Weld be used to repair copper pipes?

Yes, JB Weld can be used to repair copper pipes, but it is generally recommended only for low-pressure situations. For high-pressure plumbing, soldering or brazing is more reliable.

How effective is JB Weld on copper?

JB Weld forms a strong bond on copper, especially when surfaces are properly prepared and cleaned. It is effective for many DIY repairs and projects.

Is JB Weld heat resistant?

Yes, JB Weld can withstand temperatures up to 500°F once fully cured, making it suitable for use in high-temperature environments.

How long does JB Weld take to cure on copper?

JB Weld typically sets in 4-6 hours and fully cures in 15-24 hours. Adequate curing time is essential for a strong bond.

Can JB Weld be used for plumbing repairs under pressure?

No, JB Weld is not recommended for high-pressure plumbing repairs. Soldering or brazing is preferred for such applications.

What are the alternatives to JB Weld for copper repairs?

Alternatives to JB Weld for copper repairs include soldering and brazing, both of which provide strong, durable bonds and are better for high-pressure or high-temperature situations.

How do you prepare copper surfaces for JB Weld?

Prepare copper surfaces by cleaning and drying them thoroughly. Use a cleaning agent, like acetone, to remove any oils or residues to ensure a strong bond.

What are the limitations of using JB Weld on copper?

While JB Weld offers strong adhesion and heat resistance, it is not suitable for high-pressure plumbing applications and lacks flexibility after curing, limiting its use in scenarios requiring movement.