Does JB Weld Work on Stainless Steel? Expert Repair Tips

Ever found yourself needing a quick fix for a stainless steel item? Whether it’s a kitchen appliance, a piece of machinery, or even a car part, you might wonder if JB Weld can do the trick. This popular adhesive claims to bond just about anything, but how well does it actually work on stainless steel?

Understanding the compatibility and effectiveness of JB Weld on stainless steel can save you time and money. Before you jump into your next repair project, let’s explore whether this adhesive lives up to its reputation and how you can use it to achieve the best results.

Key Takeaways

- Surface Preparation is Crucial: Properly cleaning and roughening the stainless steel surface is essential for maximizing bond strength when using JB Weld.

- Mix and Apply Correctly: Ensure equal parts of hardener and epoxy are mixed thoroughly for effective results. Apply the mixture to prepared surfaces and allow sufficient curing time.

- Environmental Conditions Matter: Ideal application temperatures and low humidity levels enhance JB Weld’s performance. Extreme conditions may weaken the bond.

- Strong Bonding Capabilities: JB Weld offers strong adhesion to stainless steel with a tensile strength of around 3960 psi, making it a reliable choice for various repairs.

- Consult Alternatives If Needed: Depending on specific needs, consider alternative bonding methods like mechanical fasteners, welding, brazing, soldering, other adhesives, or industrial tapes for stainless steel applications.

- Understand Limitations: Be aware of JB Weld’s curing time, surface preparation requirements, and load and temperature constraints to ensure the best outcome for your repair projects.

Preparing Stainless Steel for JB Weld

Using JB Weld on stainless steel requires proper preparation. The strength of the bond depends on how well you prepare the surface.

Surface Cleaning

To achieve a strong bond, start by cleaning the stainless steel surface thoroughly. Dirt, oil, and grease can hinder adhesive performance. Use a degreaser or acetone for effective cleaning.

- Degreaser: Removes oils and grease effectively.

- Acetone: Cleans contaminants and evaporates quickly.

Cleaners can improve the adhesive bond by ensuring no contaminants remain on the surface.

Roughening the Surface

Roughening the stainless steel surface increases the bonding area. This allows for a better grip and stronger bond.

- Sandpaper: Use coarse sandpaper (e.g., 60-grit) to create a rough texture.

- Wire Brush: A wire brush can also be used to roughen the surface effectively.

These tools help create micro-abrasions, giving JB Weld more surface area to adhere to.

| Tool | Purpose | Note |

|---|---|---|

| Degreaser | Removes oils and grease | Ensure thorough coverage |

| Acetone | Cleans contaminants, evaporates quickly | Use in well-ventilated areas |

| Sandpaper | Creates a rough surface | 60-grit recommended |

| Wire Brush | Roughens the surface | Use coarse bristles |

Cleaning and roughening the surface maximizes the bond strength of JB Weld on stainless steel. Follow these steps precisely to ensure effective repairs.

Application Process

Applying JB Weld on stainless steel involves a few critical steps to achieve optimal results.

Mixing the Compound

Proper mixing ensures JB Weld’s effectiveness. The compound comes in two parts: the hardener and the epoxy. Follow these steps to mix the compound correctly:

- Combine Equal Parts: Take equal amounts of hardener and epoxy.

- Mix Thoroughly: Use a mixing tool to blend the two components. Continue mixing until you achieve a uniform color and consistency.

- Kneading for SteelStik: If using JB Weld SteelStik, knead the components together until they become tacky.

Applying JB Weld to Stainless Steel

Ensure surfaces are prepared before application. Clean and roughen the areas for a strong bond.

- Surface Preparation:

- Clean: Remove oils or contaminants using degreasers or acetone.

- Roughen: Use sandpaper or a wire brush to increase the surface area.

Once the surfaces are prepared, follow these steps:

- Apply the Mixture: Spread the mixed JB Weld onto the stainless steel area needing repair.

- Ensure Contact: Press the compound firmly onto the repair area to ensure good contact.

- Curing Time: Allow the JB Weld to cure as per the product instructions. Generally, it takes 4-6 hours to set and 15-24 hours for a full cure.

Key Considerations

Pay attention to these factors for a successful application.

Temperature: Ideal curing occurs at room temperature.

Thickness: Apply in layers if necessary, not exceeding 1/4 inch per layer.

Pressure: Clamping can improve contact and strength during curing.

Using JB Weld on stainless steel is straightforward when you follow the proper application process, ensuring a strong and durable repair.

Factors Affecting the Effectiveness

JB Weld’s effectiveness on stainless steel is influenced by several factors. Understanding these elements ensures the best results when you use this adhesive.

Environmental Conditions

Environmental conditions play a critical role in the bonding process. Various factors need to be optimized for the best results.

- Temperature: Ideal application temperatures range from 50°F to 90°F. Extreme temperatures can hinder the curing process, weakening the bond strength.

- Moisture: High humidity levels affect JB Weld’s curing time and bond integrity. A dry environment is crucial for optimal performance.

- Exposure to Chemicals: Stainless steel environments often include exposure to chemicals. Ensure JB Weld’s chemical resistance aligns with your specific application.

Load and Stress Considerations

Understanding the load and stress impact on your bonded stainless steel ensures a durable and lasting repair.

- Bond Strength: JB Weld offers a bond strength of around 3960 psi on stainless steel with proper surface preparation. Compare this with other adhesives like Loctite E-90FL, which offers 970 psi. These values indicate the effectiveness under stress.

- Shear and Tension: The joint’s design should distribute stress evenly. Stress concentration points can cause premature bond failure.

- Dynamic Loads: If the bonded area experiences dynamic loads (e.g., vibration, impact), the adhesive’s flexibility and toughness become crucial.

- Surface Preparation: Clean and roughened surfaces promote stronger bonds.

- Mixing Ratio: Properly mix equal parts of hardener and epoxy.

- Application: Ensure full contact and adequate curing time.

By considering these factors, you maximize JB Weld’s effectiveness on stainless steel applications, ensuring strong and reliable bonds.

Testing and Performance

To determine if JB Weld works on stainless steel, it’s critical to evaluate its performance in different conditions. Understanding its strengths and limitations ensures its effective application on stainless steel surfaces.

Strength and Durability Tests

JB Weld is known for its strong bonding capabilities, but its effectiveness can vary. The tensile strength of JB Weld is 3960 psi. This value reflects its maximum load-bearing capacity without breaking. But, for stainless steel applications, performance can differ due to material properties and external factors.

Key Test Metrics:

- Tensile Strength: Reflects resistance to tension. JB Weld is rated at 3960 psi, which may provide robust performance.

- Comparison with Alternatives: For context, consider Loctite E-90FL. While JB Weld boasts a tensile strength of 3960 psi, Loctite E-90FL offers 970 psi specifically for stainless steel, highlighting JB Weld’s potential variability.

Surface Preparation:

Achieving optimal results requires proper surface preparation. Clean the surface thoroughly and ensure it’s roughened to enhance bonding. Here are the necessary steps:

- Clean: Remove contaminants using degreasers or acetone.

- Roughen: Use sandpaper or a wire brush to increase surface area.

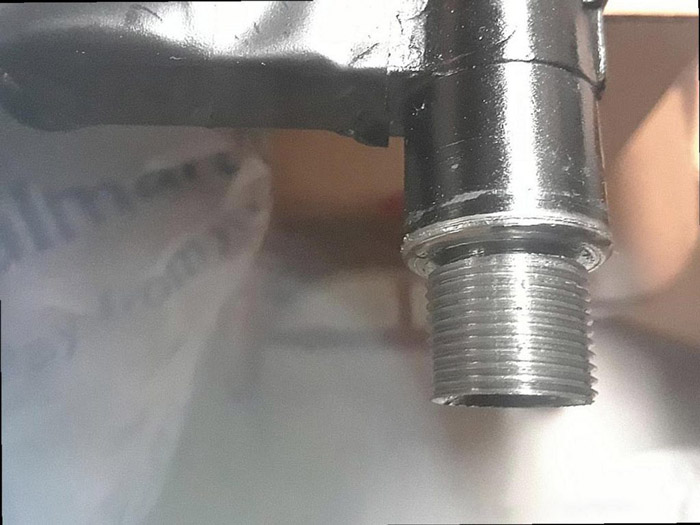

Real-World Applications

In practical scenarios, JB Weld has been used to repair minor defects in stainless steel parts. Here are some typical applications:

Repairs:

- Kitchen Appliances: Fixing cracks or joining parts in stainless steel kitchen utensils.

- Automotive Parts: Repairing minor damages in stainless steel components of vehicles.

- Machinery: Addressing small-scale defects in stainless steel machinery parts.

Application Steps:

- Mix the Compound: Combine equal parts of the hardener and epoxy.

- Apply: Ensure good contact with the repair area when applying the mixture.

- Cure: Allow 4-6 hours to set and 15-24 hours for a full cure.

Considerations:

- Temperature: Maintain an ideal temperature range during application for best results.

- Layering: Apply in layers if necessary to build strength.

- Clamping: Use clamping to improve contact and strength during curing.

These steps and considerations will help maximize the bond strength of JB Weld on stainless steel surfaces to ensure effective and long-lasting repairs.

| Test Parameter | JB Weld | Loctite E-90FL |

|---|---|---|

| Tensile Strength (psi) | 3960 | 970 |

| Specific Use for Stainless Steel | Variable | Reliable |

| Curing Time (Full) | 15-24 hours | 24 hours |

| Surface Preparation Required | High | Moderate |

By considering these factors, you can effectively use JB Weld for strong and reliable bonds in various stainless steel applications.

Pros and Cons

JB Weld is a popular adhesive known for its ability to bond stainless steel effectively. Understanding its pros and cons is crucial for making informed decisions.

Advantages

Adhesion and Strength:

JB Weld can bond stainless steel well, delivering impressive strength. It boasts a tensile strength of up to 3960 psi, making it reliable for various applications.

Temperature Resistance:

Withstand high temperatures with JB Weld. The standard product endures up to 500°F, while the stick and quick weld variants handle up to 300°F. This capability makes it ideal for repairs involving heat.

Chemical Resistance:

After curing, JB Weld resists chemicals, including butyl, methanol, and ethanol. This inertness ensures durability in environments where stainless steel faces chemical exposure.

Ease of Use:

Applying JB Weld is straightforward and doesn’t require specialized equipment. This feature makes it ideal for repairs where welding isn’t an option.

Limitations

Curing Time:

JB Weld requires adequate curing time to reach full strength. It sets in 4-6 hours but needs 15-24 hours to cure fully. This wait time might not be suitable for urgent repairs.

Surface Preparation:

For optimal bonding, surface preparation is critical. Proper cleaning with degreasers or acetone and roughening with sandpaper or a wire brush are necessary steps. This preparation can be time-consuming.

Load and Stress Limitations:

While JB Weld offers strong bonds, it’s essential to consider the load and stress on the repaired area. Excessive strain may compromise the bond over time, especially in high-stress applications.

Temperature Constraints:

Although JB Weld resists high temperatures, extreme conditions beyond its specified limits may impact its performance. High-temperature applications must stay within the recommended range.

Understanding these pros and cons helps you determine if JB Weld meets your needs for stainless steel repairs. By considering adhesion strength, temperature and chemical resistance, ease of use, curing time, and surface preparation, you can make informed decisions and achieve reliable results.

Alternative Methods

Exploring alternative methods for bonding stainless steel offers several options, each with unique properties and applications. This section delves into some of the most effective alternatives.

Mechanical Fasteners

Definition: Mechanical fasteners, such as bolts, screws, and rivets, physically bind two materials together.

Advantages:

- Strength: Offers high shear and tensile strength, suitable for heavy-duty applications.

- Disassembly: Allows for easy disassembly and reassembly.

- Availability: Widely available in various sizes and materials.

Limitations:

- Corrosion: Requires corrosion-resistant coatings or materials.

- Visibility: May not be aesthetically pleasing due to visible fasteners.

Welding

Definition: Welding uses high heat to melt and fuse metals together, forming a strong joint.

Advantages:

- Strength: Provides one of the strongest bonds, ideal for structural applications.

- Permanence: Creates a permanent joint that can withstand high loads.

Limitations:

- Skill Requirement: Requires specialized equipment and skilled technicians.

- Heat Affected Zone: Can weaken the material near the weld.

Brazing

Definition: Brazing involves melting a filler metal into the joint between base metals without melting the base metals themselves.

Advantages:

- Lower Temperature: Uses lower temperatures than welding, reducing heat damage.

- Capillarity: Filler metal flows into small gaps, ensuring a robust joint.

Limitations:

- Strength: Generally weaker than welding, though still strong.

- Preparation: Requires precise cleaning and fitting of joint areas.

Soldering

Definition: Soldering uses a filler metal with a lower melting point, bonding materials without melting the workpieces.

Advantages:

- Low Temperature: Minimizes heat damage and warping.

- Precision: Ideal for electrical and fine metalwork.

Limitations:

- Strength: Offers lower strength compared to welding and brazing.

- Joint Cleanliness: Requires clean surfaces for a solid bond.

Adhesives

Definition: Adhesives specifically designed for metal can bond stainless steel without using heat or mechanical force.

Types:

- Epoxy Adhesives: Known for high strength and durability.

- Acrylic Adhesives: Offer fast curing times and good environmental resistance.

- Cyanoacrylate Adhesives (Super Glue): Quick bonding, useful for small repairs.

Advantages:

- Ease of Use: Simplifies the bonding process without specialized equipment.

- Versatility: Suitable for different surfaces and applications.

Limitations:

- Curing Time: Some adhesives require significant curing time.

- Strength: Generally not as strong as welding or mechanical fasteners.

Tape

Definition: Industrial tapes designed for metal bonding offer quick and easy solutions.

Advantages:

- Convenience: Easy to apply without tools.

- Flexibility: Allows for expansion and contraction with temperature changes.

Limitations:

- Strength: Limited load-bearing capacity.

- Durability: May degrade over time, especially in harsh environments.

| Method | Strength | Ease of Use | Required Skill Level | Durability |

|---|---|---|---|---|

| Mechanical Fasteners | High | Moderate | Medium | High |

| Welding | Very High | Low | High | Very High |

| Brazing | Moderate to High | Moderate | Medium | High |

| Soldering | Low to Moderate | High | Low | Moderate |

| Adhesives | Low to High* (Varies) | High | Low | Moderate to High** (Varies) |

| Tape | Low to Moderate | Very High | Very Low | Low to Moderate |

- Depending on adhesive type

** Depending on environmental exposure and load conditions

Exploring these methods provides options beyond JB Weld, ensuring you find the best solution for your stainless steel bonding needs.

Conclusion

JB Weld can be a highly effective adhesive for stainless steel when used correctly. By thoroughly preparing the surface and following the recommended application steps, you can achieve strong and reliable bonds. It’s crucial to consider environmental factors, load, and stress to ensure the best results.

While JB Weld offers impressive adhesion strength and resistance to temperature and chemicals, it’s essential to weigh its pros and cons against other bonding methods. Understanding these factors will help you make an well-informed choice for your stainless steel repair needs.

Frequently Asked Questions

Is JB Weld effective on stainless steel?

Yes, JB Weld is effective on stainless steel when surfaces are properly prepared. It can provide a bond strength of around 3960 psi, making it suitable for various applications.

How should I prepare stainless steel for JB Weld?

Thoroughly clean the surface with degreasers or acetone, then roughen it with sandpaper or a wire brush. This step maximizes bond strength by removing contaminants and increasing surface area.

How long does JB Weld take to cure on stainless steel?

JB Weld typically sets in 4-6 hours and fully cures in 15-24 hours. Ensure to maintain the ideal temperature and use clamping for better results.

Can JB Weld withstand high temperatures on stainless steel?

Yes, JB Weld can withstand temperatures up to 500°F after curing, making it suitable for high-temperature applications like automotive parts and machinery.

What are the limitations of using JB Weld on stainless steel?

Limitations include the required curing time, necessity of thorough surface preparation, potential load and stress limitations, and temperature constraints.

Are there alternatives to JB Weld for bonding stainless steel?

Yes, alternatives include mechanical fasteners, welding, brazing, soldering, specialized adhesives, and industrial tapes. Each method has its own advantages and limitations.

How do environmental conditions affect JB Weld’s effectiveness on stainless steel?

Temperature, moisture, and exposure to chemicals can impact the bonding process. Proper preparation and application techniques can help mitigate these effects.

Can JB Weld be used on all stainless steel items?

JB Weld can be used on most stainless steel items if prepared correctly. It’s commonly used for kitchen appliances, automotive parts, and machinery repairs.

Should I test JB Weld before using it on stainless steel?

Yes, testing JB Weld under specific conditions can help understand its performance and ensure it meets the requirements of your particular application.

What are the pros of using JB Weld for stainless steel repairs?

Advantages include strong adhesion, temperature resistance, chemical resistance after curing, and ease of use without needing specialized equipment.